Port Structures

Keep cargo moving smoothly

Transportation by cargo ship is the lifeblood of the global transportation industry. Every day, cargo ships carrying thousands of shipping crates traverse the world and dock at ports to unload their burdens. A port, then, must be able to facilitate that traffic, supporting the flow of goods, constant ship traffic, and the heavy loads that come with it.

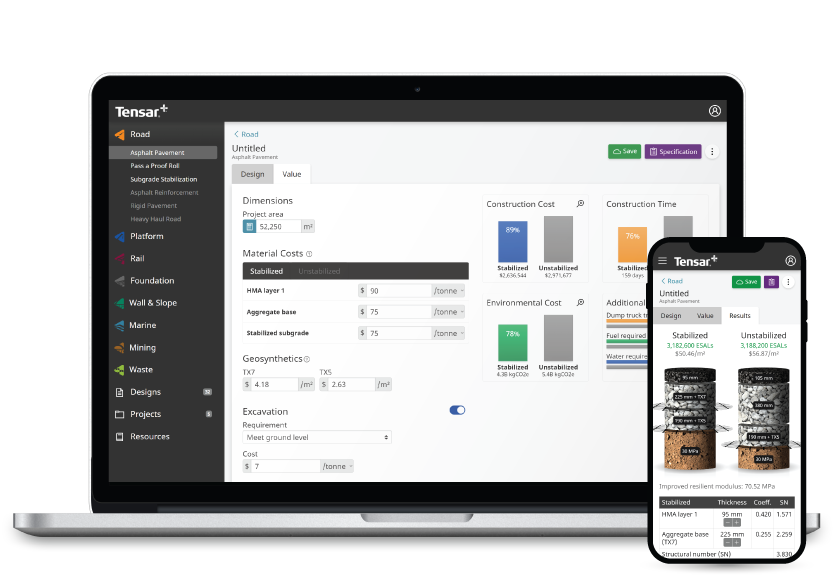

When authorities need help dealing with the challenges of port construction, they turn to Tensar’s proven technology. From heavy-duty pavements to support large equipment to rail spurs for continued transit to waterway maintenance and protection, Tensar can provide design support and solutions that reduce construction time and save on cost. The result? A busy, successful port structure that runs smoothly and requires less maintenance.

Heavy-Duty Pavements

Ports exist to load and unload the ships that travel through them, and that means heavy loads on your pavements from shipping containers and large cargo transfer equipment. Frequent heavy loads imposed on pavements can wreak havoc on maintenance budgets, and a failed pavement can cause major issues for the regular traffic of a port.

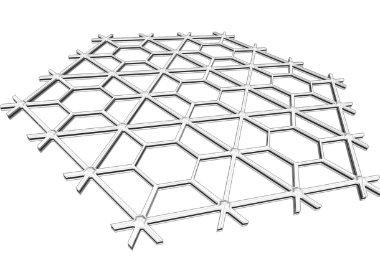

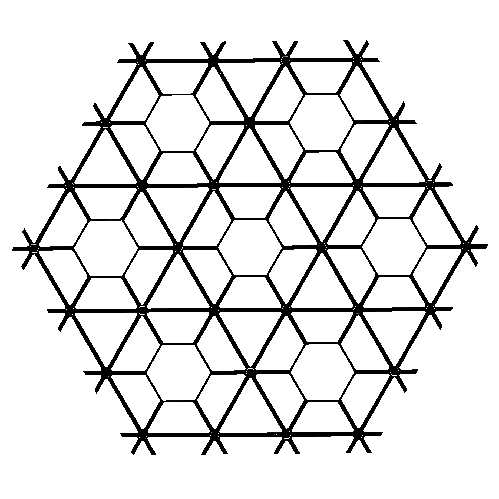

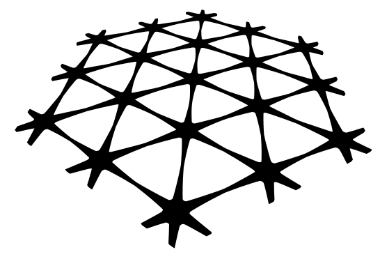

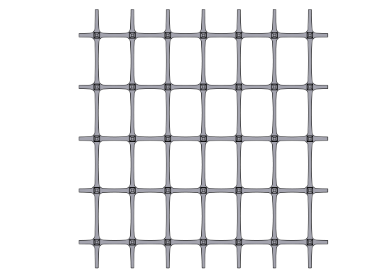

Modern heavy-duty pavement designers and contractors use Tensar geogrids to balance the requirements of these pavements with tightened construction budgets and costly aggregate supplies. Our geogrids have been proven to successfully improve pavement performance and support heavy loads while reducing construction costs.

Marine Foundation Improvement

When you’re constructing a project that serves your port and traverses a body of water, the last thing you want to see is a sinking pier. You need assurance that the ground underwater can support your design in the long term. Fortunately, Tensar’s marine products can help you improve bearing capacity and mitigate settlement, letting you design and build with confidence.

Pavement Maintenance

When pavements crack, the conventional maintenance strategy specifies placing an asphalt overlay over the existing rigid or flexible pavement. For each inch of applied overlay, existing cracks are generally deterred from reflecting to the surface by one year. Although some additional service life is gained, it’s only a temporary fix. Hot-mix asphalt (HMA) pavement reinforcement, like Tensar’s GlasGrid® system and GlasPave® paving mats, adds tensile strength to the pavements and is proven to dramatically increase the life of overlays.

Rail Track

Transitioning cargo from the sea to its final destination on land often requires a rail spur to facilitate easy transit. From light rail to heavy Class 1 rail structures, Tensar geogrids can help you stabilize ballast and sub-ballast layers, as well as reduce overall track maintenance. That frees you (and your budget) up to focus on other projects supporting the port.

Scour Control

Ports, like most waterways, are constantly exposed to dynamic conditions that can cause damage and erosion, whether that’s the regular motion of the waves and water or storms and flooding. With ships large and small moving in and out of the port every day, maintaining the integrity of the port’s waterways is vital. Tensar’s marine products can help you protect your port’s waterways against scour and erosion.

Subgrade Stabilization

When a job site features poor soils, everything grinds to a halt as construction equipment (and workers) sink into the mud – and ports are no exception. But there are solutions to stabilizing soft soils, and Tensar can help. Our geogrids are fast and easy to install and can substantially reduce the amount of fill necessary to stabilize the ground and meet your load-bearing requirements. Whether you’re stabilizing the ground under a pavement, a container storage yard, or a crane pad, we get your project back on track and moving again quickly.

.png)