Soil stabilization or ground stabilization enables engineers to build on soils that would otherwise be too weak, too compressible, or too variable. It involves the improvement of the engineering properties of a soil by mechanical or chemical means.

In road engineering, the layer of soil immediately below the road construction is referred to as the subgrade. If this layer is weak or variable, soil stabilization, or subgrade stabilization as it is commonly called by road engineers, provides an alternative to excavation and replacement of the weak soil.

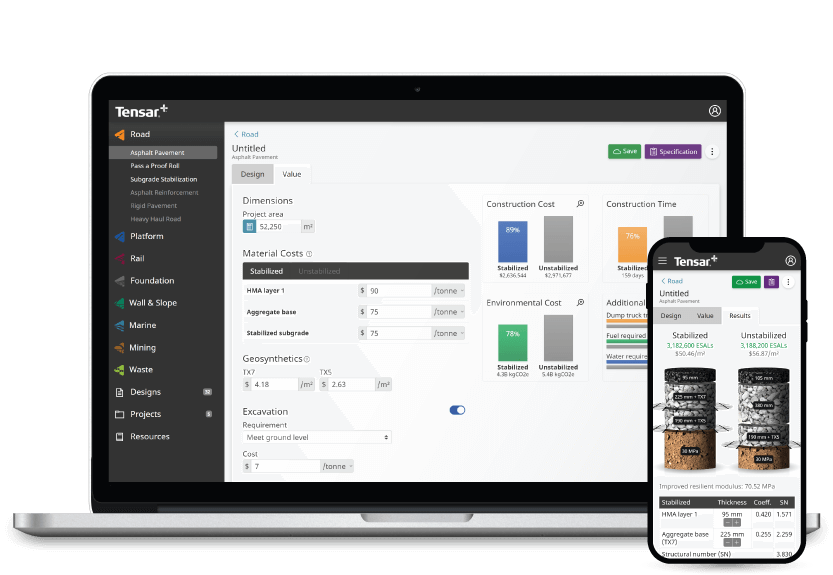

Tensar is a global leader in the design and manufacture of innovative soil stabilization technology for use in a wide range of applications, including, roads, working platforms, foundations and more. Read on to learn about the process of soil stabilization, the methods and products that can be used, and the benefits unlocked by ground stabilization techniques.

Want to navigate to a particular section? Use the links below:

- What is soil stabilization?

- Why might we need to stabilize soil?

- Soil stabilization or ground stabilization – what is the difference?

- The impact of ground stabilization on the properties of soil

- Which layers of soil are typically stabilized?

- Ground stabilization techniques

- Projects that may require soil stabilization

- What benefits can ground stabilization unlock?

- Next steps

What is soil or ground stabilization?

Soil stabilization, or ground stabilization, refers to improvement of the physical properties of a soil by the addition of a stabilizing component. This may be chemical – lime, cement, or other chemical agents combined and mixed in-situ, or mechanical – by the inclusion of a geosynthetic material like one or more layers of a stabilization geogrid.

In the context of road engineering, soil stabilization can also describe the process whereby a mechanically stabilized layer is placed over the weak soil to distribute load to the subgrade. The layer typically comprises a compacted fill material, typically an aggregate, incorporating a stabilization geogrid. In this case, the subgrade soil properties remain unchanged, but the mechanically stabilized fill layer provides protection to the subgrade and increases load-carrying capacity.

Why might we need to stabilize soil?

Everything we build above ground must transfer load into the ground. The capacity of the ground to bear that load, and the settlement associated with it, will depend on the physical characteristics of the soils.

Inadequate soil strength

The bearing capacity of a soil is dependent upon its physical characteristics – mineral composition; particle size, shape, and distribution; water content; and the confinement pressure. Inadequate soil strength will require soil stabilization, or ground stabilization.

Excessive soil settlement

Soil will deform and compress under load. At the surface, the effect of this is settlement. The soil type, arrangement of particles and the degree of saturation will determine the amount of settlement. As these factors may vary across a site, the potential for settlement varies, leading to differential settlement. Potential for excessive settlement can be overcome with soil stabilization.

Soil stabilization or ground stabilization – what is the difference?

The terms soil stabilization and ground stabilization are used interchangeably. Some ground improvement treatments with a deeper influence, such as chemical injection and dynamic compaction, are more likely to be described as ground stabilization, rather than soil stabilization. But to most engineers the two stabilization terms mean the same thing – the improvement of the physical properties of a soil by the addition of a stabilizing component to increase the bearing capacity of the ground and limit settlement.

The impact of ground stabilization on the properties of soil

The most common problems with natural soils are low subgrade strength and high compressibility. Other problems may include low permeability, susceptibility to creep deformation, freeze/thaw and shrink/swell behaviour. The objective of ground stabilization is to improve the short- and long-term properties of the soil by preventing or restricting soil particle movement..jpg)

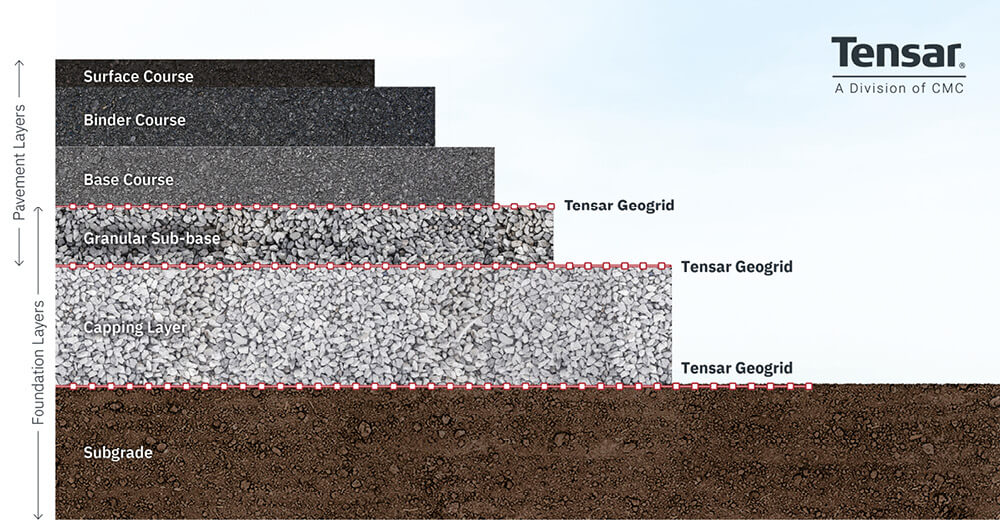

Which layers of soil are typically stabilized?

When weak or compressible ground is encountered in road, rail, and other construction, soil stabilization can improve bearing capacity and reduce settlements. Soil stabilization can be introduced at several levels.

Subgrade stabilization

The subgrade, which is the naturally occurring soil layer immediately below formation level, may be stabilized using, compaction, or chemical treatments, such as cement or lime. As an alternative the weak subgrade can be protected, and the bearing capacity improved, by subgrade stabilization using a mechanically stabilized layer (MSL).

Capping layer stabilization

The capping layer is an improvement layer placed over weaker subgrade to protect the subgrade and improve the formation stiffness. Usually constructed using a lower quality fill material compared to the subbase. The performance of this layer can be enhanced by stabilization, often enabling a reduction in thickness. Although chemical stabilization can be used, mechanical stabilization is usually adopted, where one or more layers of geogrid are incorporated into the granular fill material, forming a MSL.

Subbase stabilization

The subbase is a platform on which the main structure of the pavement is constructed. This layer is typically an unbound granular material - a well graded crushed rock or recycled aggregate. The performance of the subbase can be improved by incorporating one or more layers of geogrid to form an MSL.

Base stabilization

The road base is the primary structural layer in a flexible pavement that supports the asphalt surfacing. It can be a bound layer – usually asphalt. Or it can be unbound – using a high quality well graded crushed aggregate. Where adequate quality materials are not available, cement may be used to create a cement treated base. The performance of an unbound base layer can be improved by mechanical stabilization with a geogrid. The result is an increase in pavement life, or pavement optimization.

-(1).jpg)

Ground stabilization techniques

The most common ground stabilization techniques include:

- Over excavation and replacement of soils

- Lime stabilization, cement and other chemical soil modifiers

- Stabilization with geotextiles

- Mechanical stabilization with geogrids

- Tensar MSL

Over Excavation and Replacement

Over excavation and replacement is a soil stabilization method that involves removing weak or unsuitable soil (such as loose, soft, or expansive soil) and replacing it with stronger, more stable material (typically engineered fill like compacted gravel, sand, or crushed rock). Although this is a straightforward and reliable method, it can be extremely costly and time-consuming, especially for deep, problematic soils. It also requires disposal of unsuitable soil.

.jpg)

Chemical Stabilization with Lime, Cement and Other Chemical Modifers

Chemical stabilization involves mixing soil with stabilizing agents - most commonly lime or cement - to improve its strength, reduce plasticity and enhance its load-bearing capacity. This method is typically used when over excavation is impractical or too costly. Let's break down the difference chemical stabilization methods that are commonly encountered.

Lime Stabilization

Mixing lime into a soil to alter its characteristics has been known for centuries. More correctly termed soil modification, this technique is still used in many countries to stabilize weak soils.

The lime is mixed in place, often using specialized equipment. Most of the improvement is expected to occur within 72 hours, however the strength of the mix will continue to increase for up to a year after construction.

The addition of lime reduces the moisture content and plasticity of certain clay soils, improving workability. Lime treatment is therefore often seen as a useful temporary construction expedient by road engineers.

This method is not suitable for stabilization of non-cohesive soils, or for clays containing high sulphate levels. Laboratory classification and reactivity of the soil and appropriate mix design are critical to ensure a suitable site-specific solution.

Since lime is commonly obtained from chalk or limestone, this process has extremely high energy and CO2 costs for production. During construction, dust from in-situ mixing might affect adjacent properties and local stakeholders.

_1.jpg)

.jpg)

Cement Stabilization

Portland cement is mixed with the soil, to a pre-defined depth (typically up to 300mm). Water must be added in a second process to activate the cement. The hydrated cement combines chemically with the soil to bind the particles together, creating a stronger material. Water content must be tightly controlled to achieve the required properties.

The method is not suitable for cohesive soils and soils with more than 2% organic content, however with help of other binders some issues with these more difficult soils can be overcome.

The energy and CO2 manufacturing costs for Portland cement are high, as production entails quarrying, crushing limestone and the use of kilns operating at 1500°C.

In both temporary and permanent road applications, deformation of cement stabilized soils must be limited, as deformation can lead to cracking of the stabilized soil. In some countries it is assumed that cement improvement of soil is temporary and with time soil strength will deteriorate.

Specialized in-situ mixing equipment is available, but even with this, cement dust clouds arising during in-situ mixing can be an issue affecting adjacent properties and local stakeholders.

Other chemical modifiers

Synthetic polymers and biopolymer additives are offered for soil stabilisation. These are often proprietary agents with limited independent research to verify performance. Consequently, they are less commonly used for stabilization than cement or lime. They are typically more suited to use with granular soils with higher fines content. While they may offer a more environmentally friendly solution than lime or cement, they are often higher-cost alternatives.

Points to consider for chemical stabilization

Although chemical stabilization can be cost efficient for large areas, it's important to note that it's not effective in all types of soils like organic-rich soils. It also requires precise mixing and moisture control to achieve the desired result. Another consideration is that bad weather conditions can easily set-back construction schedules when chemical stabilization is involved since it requires dry conditions and ideal temperatures. Finally, lengthy curing times are often involved so crews must wait days or weeks for the chemicals to stabilize the soils. You can also use our helpful guide for comparing Tensar geogrid and chemical soil stabilization.

Stabilization with geotextiles

Geotextiles are permeable fabrics used in ground engineering to enhance soil behavior. They are designed to separate, reinforce, filter, protect, and/or drain when used in conjunction with soil. These fabrics are made from synthetic polymers like polypropylene or polyester, ensuring resistance to degradation by moisture, bacteria, or chemicals in the soil. There are two main types of geotextiles: woven and non-woven. Woven geotextiles are commonly used in applications like roads and rail. Non-woven are ideal for filtraion and drainage applications and often used in erosion control and drainage trenches. However, it's important to note that lateral restraint, the ability to confine particles within the stabilization plane, is the most important mechanism for soil stabilization. Since geosynthetics don't offer lateral confinement, thicker layers will need to be designed compared to geogrid stabilization to match performance specifications.

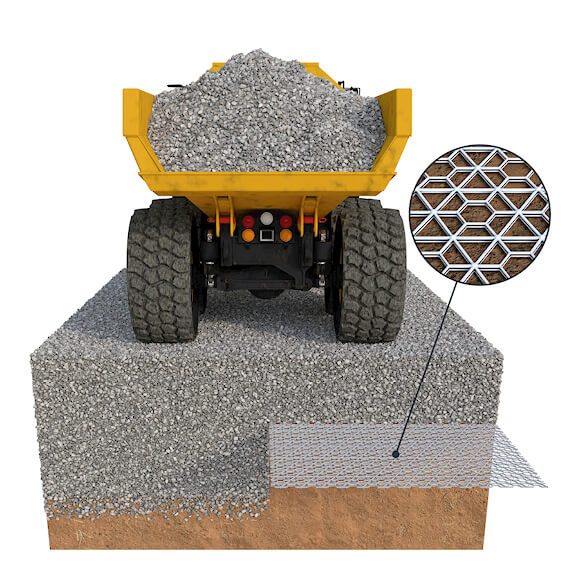

Mechanical stabilization with geogrids

Soil stabilization using geogrids has been widely adopted since the early 1980s for soft ground problems across the globe. Geogrids are supplied in roll forms and there are several types of geogrid available. The most common type used for soil stabilization uses the punched and drawn manufacturing method. Made from polypropylene, these have stiff ribs and integral junctions. The grid structure can be biaxial (with rectangular apertures), triaxial (with triangular apertures) or multi-axial (with triangular, hexagonal, and trapezoidal apertures). You can learn more about the performance of the different types in this Tensar blog post.

When an aggregate is compacted over a suitable geogrid, the aggregate particles interlock with the geogrid. Provided the geogrid has adequate in-plane stiffness at low strain, combined with strong integral junctions and a high rib profile, the aggregate particles are confined within the geogrid apertures. This particle confinement, or lateral restraint as defined above, restricts the movement and rotation of the aggregate particles in contact with the geogrid. The aggregate particles immediately above and below the confined layer interlock with the fully confined particles and are then also confined. Thus, a zone of confinement is formed around the geogrid layer. This mechanically stabilized layer has increased strength and stiffness compared to the non-stabilized aggregate.

.jpg)

Tensar geogrid (MSL)

The increased strength and stiffness of a Tensar mechanically stabilized layer (MSL) allows for a thinner aggregate layer to be used over weak soil, reducing imported material costs and associated CO2 emissions.

The properties of MSLs for a range of aggregate types and Tensar geogrid grades have been characterized by extensive testing. Design parameters have been defined and these have been validated by full-scale load testing and trafficking tests.

With suitable installation techniques, this technology can be used on extremely weak soils. Tensar can provide specific advice on the use of Tensar geogrids for mechanical stabilization over weak and variable subgrade soils.

Projects that may require soil stabilization

Weak and variable ground can hamper progress on any construction project. Very often the first problem to be solved is how to get access and operate over extremely weak soils. The next issue may be how to protect the weak subgrade from excessive deformation and remolding that would further reduce strength. The final problem may be how to improve bearing capacity to adequately support the construction above with acceptable settlements, during construction and in the longer term. These issues, in various forms, arise on the full range of construction projects.

Tensar MSLs have been used to solve these problems and more, across the globe for over 40 years.

Soil stabilization in roads and highways

As an alternative to excavating and replacement of weak subgrades soils, a Tensar mechanically stabilized capping layer or subbase can be used to protect the subgrade and increase bearing capacity. This enables a reduction in the volume of imported capping/subbase materials.

Tensar geogrids are also used to stabilize the unbound pavement layers to increase strength and stiffness, improving support to the surfacing layers and increasing overall pavement life.

.jpg)

Stabilization in railways

Mechanical stabilization of the sub-ballast increases the strength and stiffness of the track foundation. Tensar geogrids are used in track rehabilitation and new track works to increase bearing capacity.

The migration and deterioration of track ballast can be improved by mechanical stabilization of the ballast layer. Tensar geogrids incorporated into, or below, the ballast layer can extend the period between regular maintenance.

The transition in stiffness between rigid foundations, such as culverts and bridgeworks, and the adjacent soil subgrade can result in differential settlement. Multiple layers of Tensar geogrids are used to create stiffness transition zones to reduce differential settlement in these areas.

Soil stabilization for housing & residential developments

In a typical residential development, roads are often the first and last construction activity. The road layout is put in place and constructed up to subbase level to enable quick and clean access for construction of the properties. The final road surfacing may not be put in place until all properties are completed. Where weak soils are present, the cost of excavation and replacement can be eliminated by adopting Tensar mechanically stabilized capping and/or subbase layers. In some cases, this may avoid the need to expose contaminated soils, multiplying the cost savings.

The overall pavement construction thickness of residential roads can be reduced by incorporating Tensar geogrid in the unbound pavement layers. This may enable a reduction in excavation to the formation level as well as reduced imported aggregate costs. In some cases, the asphalt layers may be reduced in thickness without reducing pavement life.

Similar weak ground problems arise in commercial and industrial development sites. Tensar MSLs are often adopted as the solution.

.jpg)

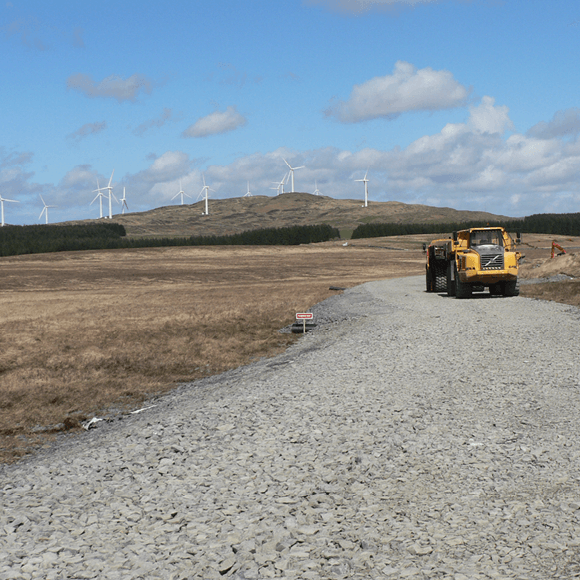

Soil stabilization for renewable energy projects

The development of onshore wind farms involves the construction of roadways to access the turbine locations. These are used during construction but are also needed for future turbine maintenance. These unsurfaced roads need to carry very high vehicle loads. Very often wind farm sites are located in remote areas of weak soil. Many in the United States are on organic soils. On these organic soils Tensar MSLs are used to create access roads, minimizing the disruption to the required aggregate and significantly reducing the volume of imported materials.

Crane access pads adjacent to the turbines need to carry high load with limited settlement. Tensar MSLs have been used for the foundation of these crane pads.

Stabilization of airport pavements

Deformation of the base layer and subgrade below pavements leads to accelerated deterioration and reduction of pavement life. Tensar MSLs have been used in airports to strengthen the foundation of new runways and taxiways and reduce differential settlement.

.jpg)

What benefits can ground stabilization with Tensar geogrid unlock?

Soil stabilization, turns weak variable soils into workable engineering materials, enabling construction to proceed. By changing the characteristics of the soil or by capping weak soil layers, the bearing capacity is increased to a sufficient extent to carry construction and service loads without excessive deformation.

Reducing project costs

By avoiding the need to excavate and replace weak soils with imported fill, the cost of construction can be reduced. Geogrid stabilization provides an improved and more consistent bearing capacity across the site. This allows the designer to adopt more economical designs for the work above. Pavement design need not be overly conservative to allow for subgrade variation. Rail trackbed design can reflect the improved bearing capacity leading to more economical design.

Increasing the profitability of projects

Contractors faced with gaining access over weak soils have traditionally placed thick fill layers to create an acceptable working surface for laydown yards, equipment movements and storage areas. Project profitability relies on the construction team to get in, get the job done, and get out, as quickly as possible. Soil stabilization can rapidly provide a strong working surface without the cost and time associated with importing large volumes of fill. The time saved can have a positive impact on project planning and overall project profitability.

Tensar mechanical stabilization of unbound layers in the road pavement offers the opportunity to reduce overall pavement thickness, reducing both bound and unbound layers, without reducing service life. As a value engineered alternative to a non-stabilized pavement design this can offer major construction cost and time savings, increasing project profitability.

Meeting sustainability targets

By reducing the volume of imported fill materials and in some cases the export and disposal of unsuitable, sometimes contaminated soils, construction related CO2 emissions are reduced. This comes as a direct result of the reduced transportation, plus quarrying and compaction related emissions.

Resilience for Extreme Weather Conditions

Soil stabilzation solutions are being employed where problems related to expansive soils, freeze/thaw cycles and loss of permafrost, due to extreme weather conditions. Incorporating mechanical stabilization into new construction provides greater resilience for the future where potential for these problems exists.

Next Steps

This guide has offered a comprehensive look at ground stabilization, exploring why we need to stabilize soils and the methods and products that make it possible. Tensar offers a range of industry-leading soil stabilization products suitable for various industries and markets, including:

- Roads, Pavements & Surfaces

- Rail

- Renewables

- Housing Residentialand Residential

- Commercial & Industrial

- Airports

Tensar’s design team can also available to review your project free of charge to find any hidden cost or time savings. To do this, simply visit our design support page.

.png)