Railway Structures

Cost-effective, high-performance rail track design

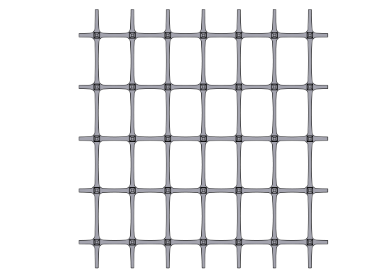

Increased transportation of goods coupled with rising construction costs have rail owners seeking cost-effective solutions to build new track. This increased demand also has owners grappling with lost productivity from ongoing maintenance issues. Tensar geogrids provide a predictable, cost-effective solution for the stabilization of ballast and sub-ballast layers that includes many advantages. Key benefits include lower up-front construction costs and extended maintenance intervals.

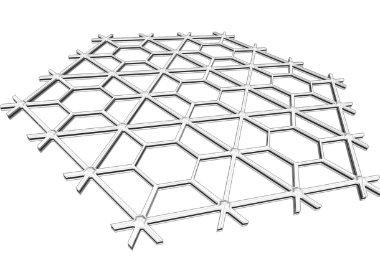

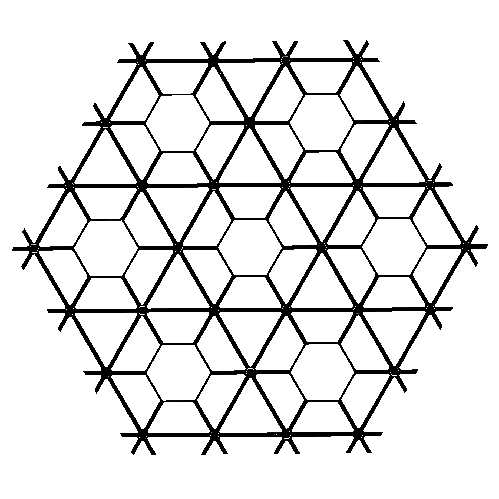

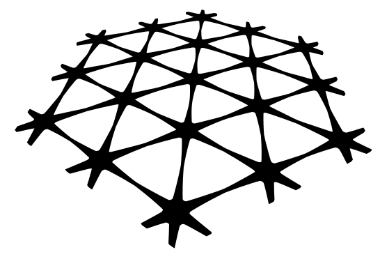

Tensar geogrids benefit rail track systems in two ways: sub-ballast and ballast stabilization. In sub-ballast stabilization, geogrid is installed at the bottom of the sub-ballast. The geogrid distributes the imposed loads more efficiently over the underlying subgrade, leading to a reduction in the required sub-ballast layer thickness. With ballast stabilization, the geogrid is installed between the ballast and sub-ballast layers. This limits lateral spread and thereby minimizes track settlement. Given a specific set of soil and proposed loading conditions, a full rail track design section can be developed by Tensar to include a trackbed section in full compliance with regulatory guidelines (e.g. AREMA).

Beyond the track stabilization and cost efficiency benefits for trackbed development and maintenance, using Tensar geogrids supports rail asset resilience. Infrequent, large-scale events can cause enormous disruption and damage. In such situations, geogrid is an essential tool for minimizing infrastructure damage, reducing transport disruption, and improving response and recovery time for rail track systems.

We offer a one-hour webinar to introduce you to using geogrid for mechanical stabilization of ballast and sub-ballast in rail track structures.

Track Maintenance

Since track maintenance is a significant and ongoing expense, lifecycle cost savings are an additional benefit of using Tensar geogrids. Over the long term, geogrids preserve the integrity of the railway track structure by confining the ballast and sub-ballast layers and preventing lateral spread. This typically extends the period between maintenance operations by a factor of three to five times. Finally, in reducing the deflection of the trackbed during loading, Tensar geogrids extend the life of mechanical track components including rails, ties, and insulated joints.

New Construction

Tensar geogrids can save up to $30,000 per linear mile of track by significantly reducing the required trackbed thickness (and still meet the required factor of safety). The ease of geogrid installation not only accelerates construction schedules, but also eliminates the cost of special labor and equipment. And with the option to install geogrids in wet conditions, contractors can maximize their productivity in inclement weather. Since Tensar geogrids can be installed directly over existing weak subgrade soils, the costs associated with subgrade excavation, disposal, and replacement or chemical treatment (along with the curing time for chemical treatment) can be eliminated. With shallower excavation, the potential costs associated with the relocation of utilities can often be eliminated as well.

Ongoing Research

Tensar geogrid technology has been the subject of extensive independent research and development and approved by AREMA, Network Rail in the UK and National Rail Authorities worldwide. Recently, Penn State University presented research findings on how Tensar geogrid systems influenced ballast movement, rotation and displacement at the annual Transportation Research Board (TRB) meeting in 2016.

.jpg?width=580&height=580&ext=.jpg)

.png)