Waste and Landfill Support

Proven solutions for waste management sites

The decreasing number of potential waste containment sites, along with the general public mindset of “not-in-my-backyard,” makes optimization of sites a top priority for owners and engineers. Whether serving the public or private sector, owners and operators of waste management facilities can all agree on three priorities: operational economy, longevity, and environmental security. Today’s state-of-the-art waste containment facilities often require the regulated use of specially designed systems to assure long-term collection, detection, and containment. When placed over marginally stable or highly compressible foundation soils, the long-term performance of these systems becomes even more critical.

Tensar solutions maximize the economy, lifespan, and security of landfills, disposal sites, and closures with proven solutions for landfill construction, expansion, and capping/closure. Further, owners and engineers depend on our systems to build industrial containment facilities for fly ash, mine slurry, and heap leaching projects. From reinforced slopes to haul/access roads stabilization, we have a solution to meet your specific budget and performance needs.

Capacity Improvement

As site availability decreases, compliance increases, and budgets are tested to their limits, the need to get the most out of (and into) existing landfills is more crucial than ever. The use of engineered berms allows for a custom-engineered reconfiguration of a waste containment facility, maximizing disposal capacity while meeting all regulatory requirements and enhancing the overall revenue potential of the site.

Capping/Closure of Brownfields

Oftentimes, there is great risk associated with constructing over a closed landfill. Generally, these properties are cheap and often located in unfavorable locations. The unknown composition and degradation of the underlying fill can be challenging to assess. Differential and total settlement can cause unwanted problems for structures, pavements, or roads that are built over closed landfills. Tensar can offer engineered, cost-effective solutions to the challenges that building over a closed landfill can bring. This can deliver substantial savings to the owners and land developers by allowing the use of a covered landfill site that might otherwise have been considered unusable.

Haul/Access Roads

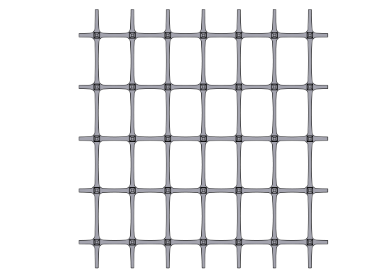

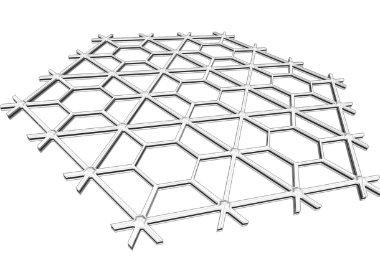

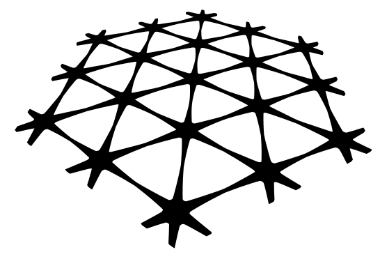

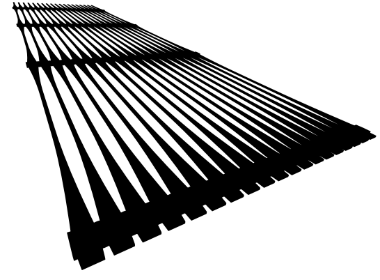

Weak subgrades pose the greatest challenge to the performance of an unpaved access or haul road. Left untreated, a weak subgrade subjected to continuous heavy traffic will quickly deform, causing the road surface to rut, pothole, “washboard,” and ultimately deteriorate beyond use. Tensar geogrids are designed to reduce construction-induced or in-service stresses applied to weak subgrades. Geogrid and aggregate interlock to create a mechanically stabilized layer (MSL) to evenly distribute the load, increasing bearing capacity and ensuring longer-term stability and performance.

Liner Support

Tensar can design a protective liner support system using Tensar geogrids to limit the strains within the existing liner to manageable levels. A liner support solution allows you to create new, usable airspace via vertical or horizontal expansion of an existing cell, as well as construct a new landfill cell over marginal foundations. By reinforcing the lining system, you gain additional cost savings by not having to permit a new site, as well as relatively fast regulatory approval.

The components of a containment system typically include synthetic or clay liners together with synthetic drainage media. The performance of these components is critical. When liners aren’t reinforced during construction, a rupture or leak could result in contamination of the surrounding groundwater, as well as have costly regulatory penalties and permit violations. And if a liner ruptures, the repair cost can skyrocket quickly due to excavation. Geogrids can help prevent these dangerous and extensive repairs.

Veneer Stability

Soil covers are often employed at waste containment facilities to provide a protective cover for other abrasion or ultraviolet (UV) sensitive geosynthetic components of a liner system. The weight of these soil or aggregate veneer covers, in combination with the inherently weak interface friction characteristics between many commonly used geosynthetics, may facilitate a sliding failure and possibly result in a rupture within the lining system. Our engineered solutions, using Tensar uniaxial geogrids, can support the soil cover, reducing the stress placed on the underlying lining system and ensuring the long-term stability of the waste containment facility. Since not all projects involve a liner, we also have solutions for non-lined applications.

The Right Solution for the Right Site

Tensar offers economical waste solutions that help municipal solid waste sites with trash landfills, industrial solid waste sites with tank farms and sludge ponds, and energy facilities with landfills and impoundments.

.png)