.jpg?width=580&height=580&ext=.jpg)

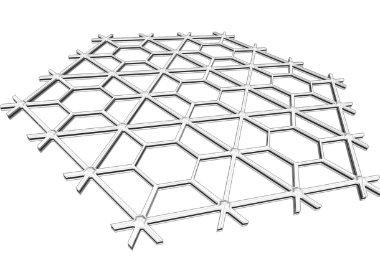

TrackTex™ Anti-Mud Pumping Solution

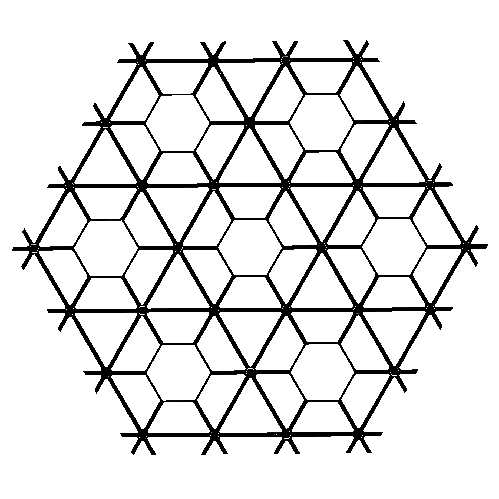

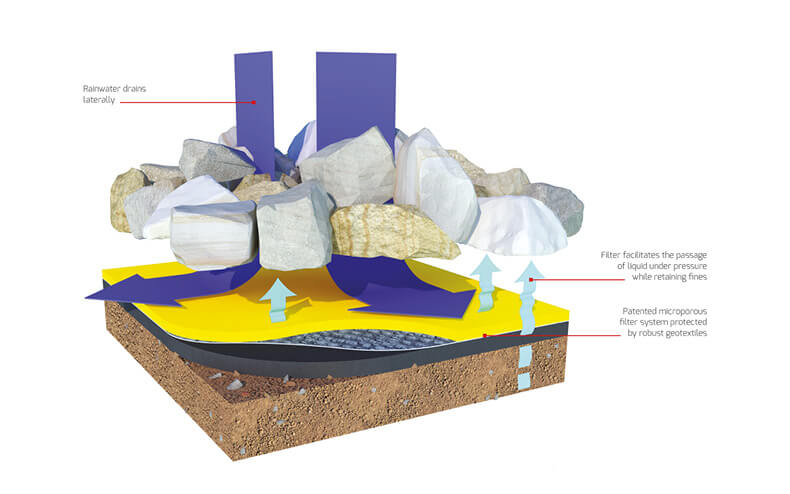

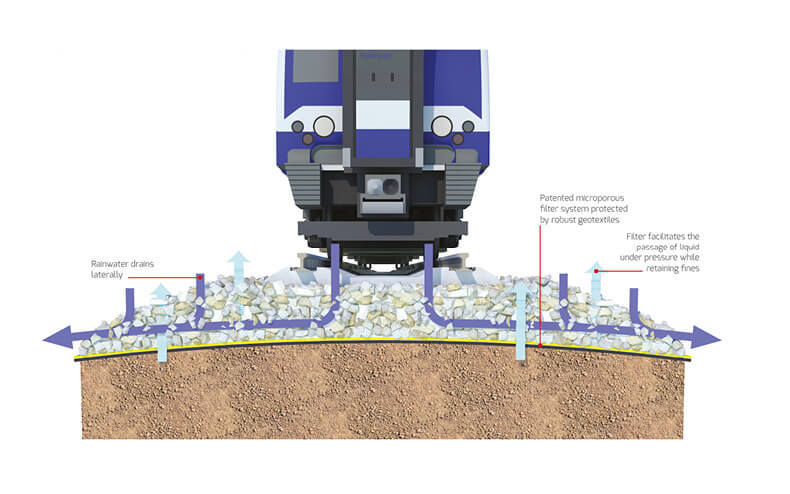

- Prevents subgrade fines and slurry from migrating up into the ballast

- Facilitates desiccation and drying of the existing subgrade

- Faster to install than other conventional solutions to address mud pumping

- Proven sufficiently robust to installation and operational damage

- Flexible to conform to uneven subgrade formations to eliminate slurry inducing voids

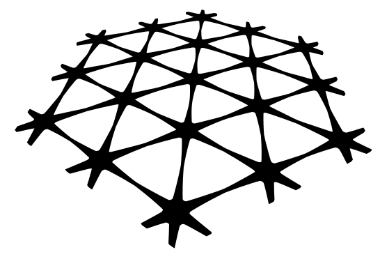

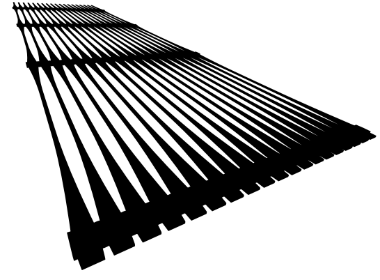

TrackTex is designed to cost-effectively address mud pumping problems in various rail track environments like treatment on mainline, secondary line, high tonnage lines, and rail yards. It also serves as preventative maintenance for crossings, diamonds, turnouts, switches, and bridge approaches. This patented geosynthetic is designed with a special filter system that improves trackbed quality over time and has been proven to significantly increase maintenance intervals. TrackTex can also be combined with a Geogrid to provide enhanced trackbed stabilization and section stiffness.

Rainwater is unable to penetrate the micro-porous filter and is drained laterally to the side of the track while pore water below the Tracktex is relieved upwards under cyclic loading which aids residual slurry to dry out as the pore water is dissipated. It can effectively facilitate the passage of liquid under pressure, but the pores block clay fines from coming through. Without pressure, water cannot pass through the filter, so that any underlying clay formation will, over time, dry out and have an improved modulus.

TrackTex is a trademark of GEOfabrics based in the United Kingdom. Tensar is the preferred distributor in the United States.

.jpg?width=580&height=580&ext=.jpg?width=300)

.jpg?width=300)

-(1).jpg?width=300)

-(1).jpg?width=300)