What is a temporary site access road?

Temporary site access roads are regularly required on construction sites. Also known as temporary haul roads, they provide access for heavy construction vehicles carrying materials and equipment needed to complete the project at hand. Because these roads are temporary, they tend to be constructed from a granular fill or aggregate placed on existing ground. The granular fill or aggregate acts as the road surface itself. Temporary site access roads can be as short as a few tens of feet or long enough to extend several miles.

Temporary access road design and construction methods

Although an access road may only be needed for a short period, it should be designed based on the anticipated traffic load it will carry over its operational life. The design procedure identifies what thickness of granular fill is needed to carry the traffic load. An access road design assessment will take several factors into account for the site under consideration:

• Existing ground strength—normally expressed as a California Bearing Ratio (CBR), undrained shear strength or stiffness modulus

• Anticipated traffic load—expressed as a number of vehicle visits of differing type and configuration (e.g. concrete mixers, steel delivery vehicles) from which a number of Equivalent Single Axle Loads (ESALs) can be calculated*

• Granular fill grading — This refers to the quality of the aggregate used to build the road and would typically be classified using a particle size distribution curve

• Target surface deformation or rut depth — A serviceability target for the road surface after trafficking

*It’s important to note that the critical time for building an access road is the construction phase itself, since the vehicles delivering the granular fill are travelling at their closest point to the subgrade soils.

Considerations for site access with poor ground conditions

Temporary site access roads are commonly used in areas with poor ground conditions and unstable soil. The weak or variable ground means traditional methods of road construction are not always possible. Not only do poor ground conditions pose a significant threat to the structures themselves, they also pose safety risks for workers and machinery throughout the duration of construction. Below are just a few considerations when assessing the suitability of ground conditions:

Differential settlement

Soil experiences differential settlement when there is a shift in internal stress. It occurs when there are changes in the soil moisture content or as a result of increased loading that exceeds the bearing capacity of the ground.

Weak and compressible soils

Different soils react differently to certain conditions. For example, excess rainfall and floods can cause soil to soften, whereas clay can experience contraction when rainfall is reduced.

Severe weather

Adverse weather conditions throughout a construction project can have a negative impact on ground conditions. Differing soil types can affect drainage and lead to potential flooding on site. This can pose a risk to both the structure once built and the contractors and machinery during construction.

Historic use of the site

Previous work and historic structures such as mines can have an impact on the present ground conditions. For example, decommissioned mines can pose a high risk of sinkholes and these cavities risk collapse if significant pressure is placed upon them.

What are the benefits of using geogrids in temporary access roads?

Many temporary access roads are needed where existing ground conditions are poor as well as variable. Often, this means that using traditional methods like over-excavation/replacement can require a significantly thick layer of stone to cater for the anticipated traffic load. It will often need regular maintenance to address surface deformation and rutting which can slow operations over the longterm.

Stabilization geogrids can offer significant benefits to access road design in terms of reducing the thickness of the requuired granular layer to build the road. This results in:

- Lower construction cost

- Faster construction time

- Reduced environmental impact

Tensar’s involvement in temporary site access road construction

Incorporating a stabilization geogrid within a granular roadway forms what’s known as a mechanically stabilized layer (MSL). Tensar geogrids have been used in temporary access road design and construction for many decades. Geogrid technology has been developed and applied to thousands of miles of roadway constructed over various ground conditions that can deal with a large variation of loads.

However, it’s important to recognize that the measurable benefits from including geogrids in temporary access roads requires more than parameters on a product specification sheet. As mentioned earlier, the design of granular access roads is typically based on empirical data from testing and research. The ability of the geogrid to interlock and confine the aggregate subjected to traffic loading is fundamental to deliver enhanced performance of MSL. This enhanced performance can only be measured through full-scale in-ground trafficking testing. This is also the most effective way of quantifying the benefits of a geogrid in a granular road.

To this end, Tensar has participated in extensive research carried out over multiple decades, including full-scale trafficking trials. These studies have demonstrated the following:

• No one geogrid parameter has been identified as a good indicator of expected performance.

• The ultimate tensile strength of a geogrid is a poor indicator of expected trafficking performance. Read more here.

• It’s the effect of the geogrid in combination with the granular aggregate that gives the greatest benefit to the road. This effect is known as stabilization.

• Geogrid-specific stabilization factors can be derived to allow the effect of a geogrid to be modelled in the temporary haul road design assessment.

The interaction between the granular particles and the stiff geogrid structure is critical (Figures 2 and 3).

Figure 2: Granular particles confined within the stiff geogrid apertures

.jpg)

Figure 3: A Tensar mechanically stabilized layer consisting of InterAx geogrid and granular fill

How can we quantify the benefits of geogrids for temporary site access roads

Working on weak or variable ground usually presents considerable construction challenges, so designing a secure MSL prior to construction is essential. By using the Tensar+ design software, a MSL can be designed prior to construction, further protecting the subgrade and improving bearing capacity. Tensar’s subgrade stabilization design methods and solutions are widely accepted and utilized worldwide.

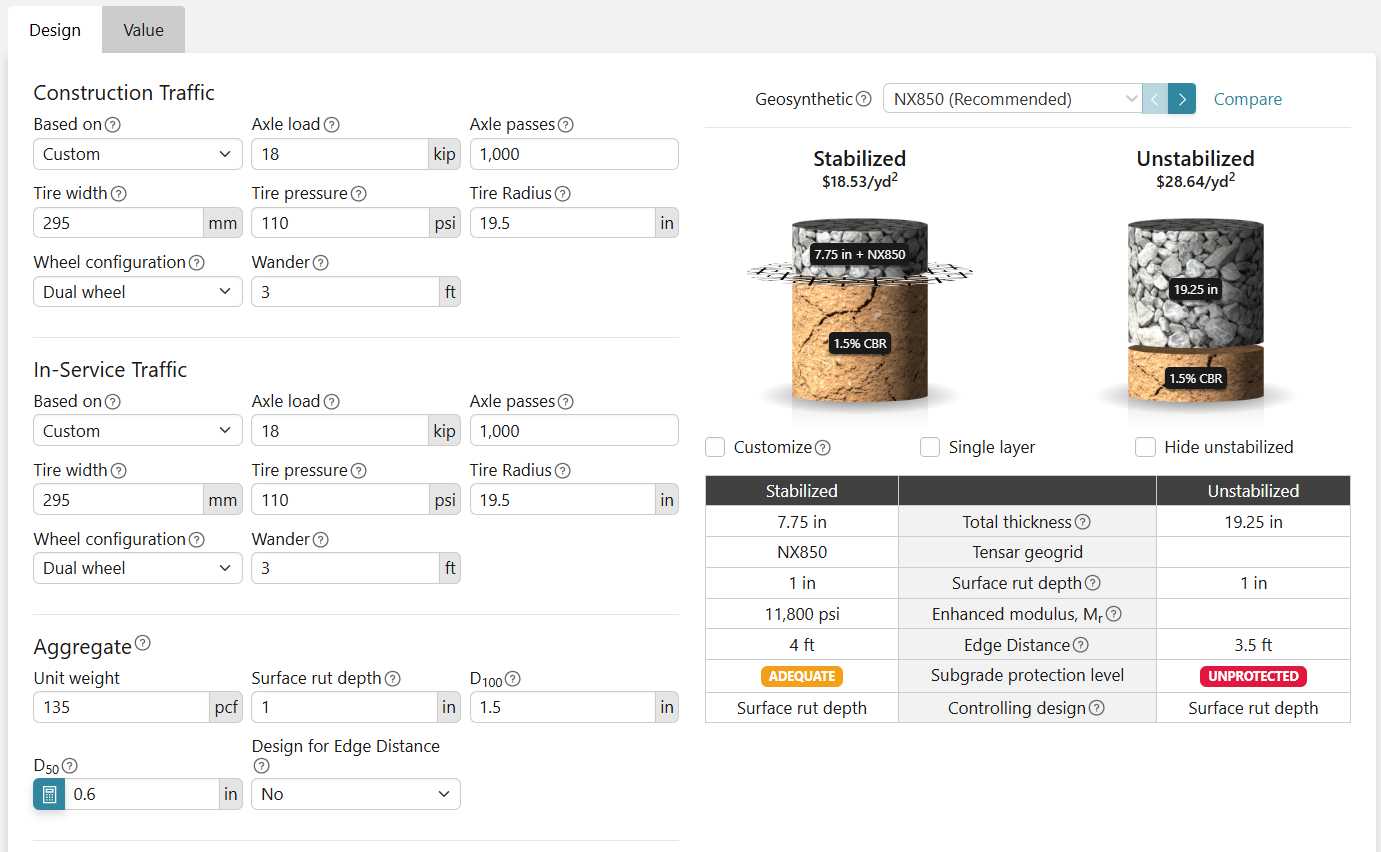

Figure 4: Tensar+ Unpaved Road & Subgrade Stabilization tool comparing a non-stabilized section on the right with a MSL on the left

Using this software, temporary haul road designs with and without stabilization geogrids can be compared and assessed - and savings can then be quantified. Including a stabilization geogrid in a granular access road will reduce the required non-stabilized thickness by up to 50%.

While other mechanisms like geotextiles are available, they rely on tensile strength. This means deformation is likely to develop in the roadway. However, a stabilization geogrid doesn’t deform like a “hammock” but remains level as part of the MSL. This protects the subgrade from permanent deformation (Figure 5).

Figure 5: The difference between geogrids and geotextiles. Learn more about comparing geogrids and geotextile.

How do geogrids match project conditions?

• Existing ground conditions

• Anticipated traffic load

• Grading of granular fill to be used in the access road

• The temporary nature of the access road

The different grades of stabilization geogrid aren’t based on varying levels of strength, but different sizes of aperture and different product stiffness to suit specific project conditions. This means that a wide range of fill types can be used to form the MSL, from coarse fill all the way down to a sandy material (Figure 6). They can also be used on a wide variety of subgrade soils to stabilize temporary access roads to construction sites.

Golden Hills Wind Farm

Access roads needed to be constructed to support heavy turbine loads with a tight schedule for completion. Limited water access for the moisture treatment of the aggregate layer also posed a challenge. The original design section called for 10 inches of AB over geotextile with subgrade compaction.

The Tensar design reduced the section to 6 inches of AB over Tensar multi-axial geogrid and maintained the required performance. This solution also reduced the water usage, required material and saved valuable time. Approximately $630k in construction costs were saved. This also resulted in several environmental benefits like avoiding pollution of nearby water sources.

Sound Transit Access Road

Seattle, Washington

A contractor was building an access road over historic marsh land when the crew encountered a high water table. The original solution to stabilize the subgrade used a non-woven geotextile and 2-3 ft of rock; however, the roads quickly rutted and became unserviceable for their heavy dump trucks.

Tensar offered a soil stabilization solution using multi-axial geogrid. The Tensar design reduced the required aggregate thickness and allowed the use of 3/4" aggregate instead of the expensive ballast rock needed with geotextile. Ultimately, this solution cut construction time in half while keeping costs similar to the original budget.