Does Tensile Strength Matter in Ground Stabilization?

by Bryan Gee, P.E., on September 12, 2023

Many geosynthetic specifications focus on tensile strength as an indicator of better performance. But some properties that are important for reinforcement applications, like retaining walls, don't apply to stabilization applications like roadways. A minimum tensile strength is needed to make sure the product can withstand aggregate placement and compaction, but performance depends on many factors, none of which are directly correlated.

The Difference Between Reinforcement and Stabilization

Reinforcement is the stress-strain behavior that comes into play when loads are applied continuously to a soil mass, like in a retaining wall or slope. The various types of stress applied to the reinforced soil mass translate into tensile stress on the geosynthetic. When geosynthetics are used in walls and slopes, tensile strength is an important input to the design and correlates to in-ground performance. It’s easy to see how this can cause confusion when looking at stabilization applications.

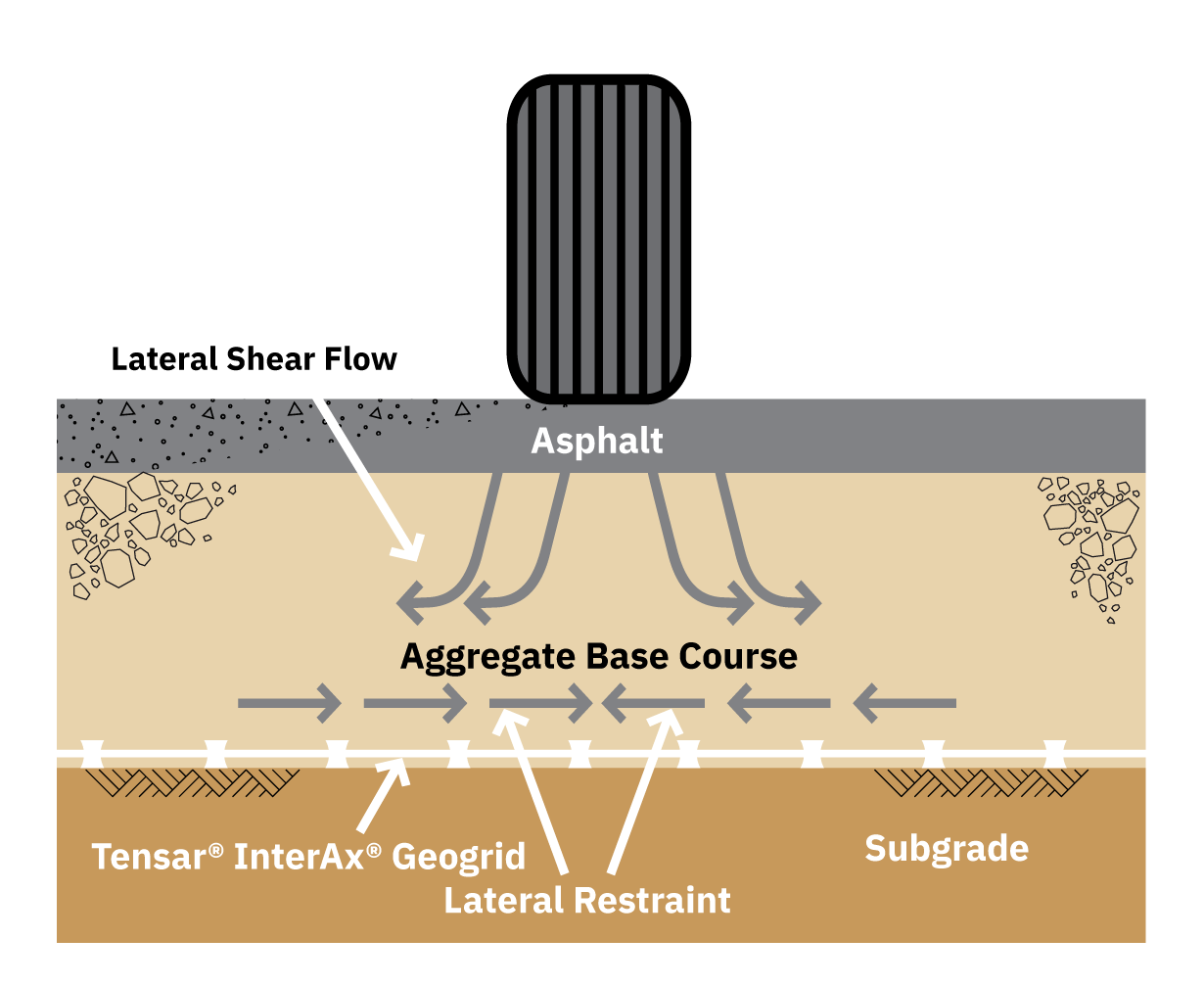

Stabilization improves the performance of unbound granular material so that deformation is reduced when subjected to loading. The U.S. Army Corps of Engineers considers lateral restraint, the ability to confine aggregate particles, the primary stabilization mechanism for geogrids. Note that in a stabilization application, the loading is applied intermittently to the composite layer of geogrid and aggregate, and is perpendicular to the plane of the geogrid. In a reinforcement application, the loading is constant and is in the plane of the geogrid. A stiffer, stabilized layer resists rutting and improves bearing capacity compared to an unbound layer.

Many assume that geotexiles are a great solution to stop rutting in roadways because they equate high tensile strength with better in-ground performance. However, multiple full-scale, highly controlled tests conducted over the years have proven that soil tensile strength is not an indicator of performance. Stabilization geogrid like Tensar InterAx has apertures that allow granular materials to interlock. This interlock confines the granular particles to keep them from spreading laterally and minimizes the movement of the material. This also means you can get the same level or better performance using less aggregate.

An excellent, real world example of this was the Canning Road project in Ontario. The Hamilton Township was experiencing project backlog due to COVID-19 restrictions at the time. The original design called for digging down 600 mm, placing a woven geotextile and installing new aggregate to repair the road.

After determining the subgrade strength, Tensar+ Software was used to present a range of potential solutions to the owner. Solutions included geotextile fabric, TriAx® geogrid and Tensar's advanced InterAx® geogrid. Ultimately, the Township chose the higher performing InterAx geogrid because it required the least amount of excavation, which in turn reduced material costs and necessary labor. Since the Tensar InterAx geogrid design reduced the excavation and required less aggregate, the work was completed in half the time and saved 40% of the cost compared to the original geotextile design.

The bottom line – higher tensile strength does not correlate to better performance for soil stabilization.

Want to learn more about geogrid for soil stabilization? Visit www.tensarcorp.com

Comparing Geogrids

There are dozens of geogrids and other geosynthetic products on the market. How do you know which is right for your project's needs? When it comes to roadway construction, the keys are proper design and testing to validate performance.