No Excavation Required: A Smarter Way to Rehabilitate Trackbeds

by Don Herbert, on July 30, 2025

The Hidden Risk Beneath the Rails

What if the most disruptive and expensive railbed problems are the ones you can’t see?

Poor subgrade conditions are a common but often overlooked cause of delays, cost overruns, and operational risk in rail infrastructure projects. These underground and unseen failures exacerbate the challenges railroad owners and transit agencies already face like dealing with aging assets, limited jobsite access, tight construction windows, and pressure to meet sustainability goals.

The High Cost of Undercutting

Traditionally, railroads and transit agencies remove weak soils beneath trackbeds through a process called undercutting. However, this method is expensive, time-consuming, and logistically complex. It increases jobsite congestion, safety risks, traffic disruption, and emissions from trucking and material handling. The carbon footprint can be significant, particularly across large rail networks. But, what if undercutting could be avoided?

A Shift Underground: Geosynthetics Gain Ground

Rail agencies are increasingly turning to geogrids and geocomposites—engineered materials designed to stabilize weak subgrades without excavation.

By stabilizing weak soils and stopping the upward movement of fines, geosynthetics help keep ballast clean, stable, and long-lasting. The results include faster construction, fewer disruptions, lower maintenance needs, and a durable alternative to costly undercutting.

What Operations, Safety, and Asset Leaders Should Know

Stabilizing the subgrade in place using a solution that combines geogrid and geocomposites offers significant operational and strategic benefits:

When This Approach Makes Sense

Excavation-free stabilization using geogrid and geocomposite materials are well-suited to the realities of modern rail infrastructure projects, especially in places where time, access, and soil conditions complicate traditional construction methods. This approach can offer substantial advantages when:

The Chicago Transit Authority (CTA) faced significant challenges between the Dearborn Subway and Illinois Medical District Station due to subgrades with an Initial Bearing Value (IBV)—a measure of soil strength and ability to support heavy loads—below 4%, combined with poor drainage and restricted site access. Conventional methods would have required extensive excavation, importing large volumes of aggregate, and causing considerable delays. The use of geosynthetics drastically reduced site traffic, limited heavy equipment operation in congested areas, and enabled efficient construction without the typical urban disruption.

.jpg?lang=en-US&height=263&width=350) The CTA project team implemented an innovative approach using Tensar InterAx geogrid combined with TrackTex anti-pumping geocomposite. The complete solution involved placing 8 inches of sub-ballast and 12 inches of ballast on top of the geogrid and geocomposite materials, eliminating the need for excavation.

The CTA project team implemented an innovative approach using Tensar InterAx geogrid combined with TrackTex anti-pumping geocomposite. The complete solution involved placing 8 inches of sub-ballast and 12 inches of ballast on top of the geogrid and geocomposite materials, eliminating the need for excavation.

This method resulted in significant savings: approximately $500,000 in project costs, nearly 1,200 truckloads of material avoided, and a reduction of over 50 tonnes of CO₂ emissions. The track installation was completed on schedule, minimizing disruption to surrounding roads and infrastructure.

Rethinking the Trackbed

CTA's success with excavation-free stabilization on the Congress Line is not an isolated case—it's a compelling model for more efficient, effective, and sustainable trackbed rehabilitation. As rail agencies nationwide tackle aging infrastructure, they have a clear choice: continue traditional excavation methods or adopt innovative, scalable, and low-disruption alternatives.

Agencies exploring this approach can benefit from early planning, supported by case studies, design tools, and field-proven insights available through Tensar. Early engagement helps identify opportunities to deliver measurable gains in cost, time, and environmental impact. When used strategically, excavation-free stabilization isn’t a workaround, it's a forward-looking upgrade to how you can build and maintain trackbeds.

What if the most disruptive and expensive railbed problems are the ones you can’t see?

Poor subgrade conditions are a common but often overlooked cause of delays, cost overruns, and operational risk in rail infrastructure projects. These underground and unseen failures exacerbate the challenges railroad owners and transit agencies already face like dealing with aging assets, limited jobsite access, tight construction windows, and pressure to meet sustainability goals.

The High Cost of Undercutting

Traditionally, railroads and transit agencies remove weak soils beneath trackbeds through a process called undercutting. However, this method is expensive, time-consuming, and logistically complex. It increases jobsite congestion, safety risks, traffic disruption, and emissions from trucking and material handling. The carbon footprint can be significant, particularly across large rail networks. But, what if undercutting could be avoided?

A Shift Underground: Geosynthetics Gain Ground

Rail agencies are increasingly turning to geogrids and geocomposites—engineered materials designed to stabilize weak subgrades without excavation.

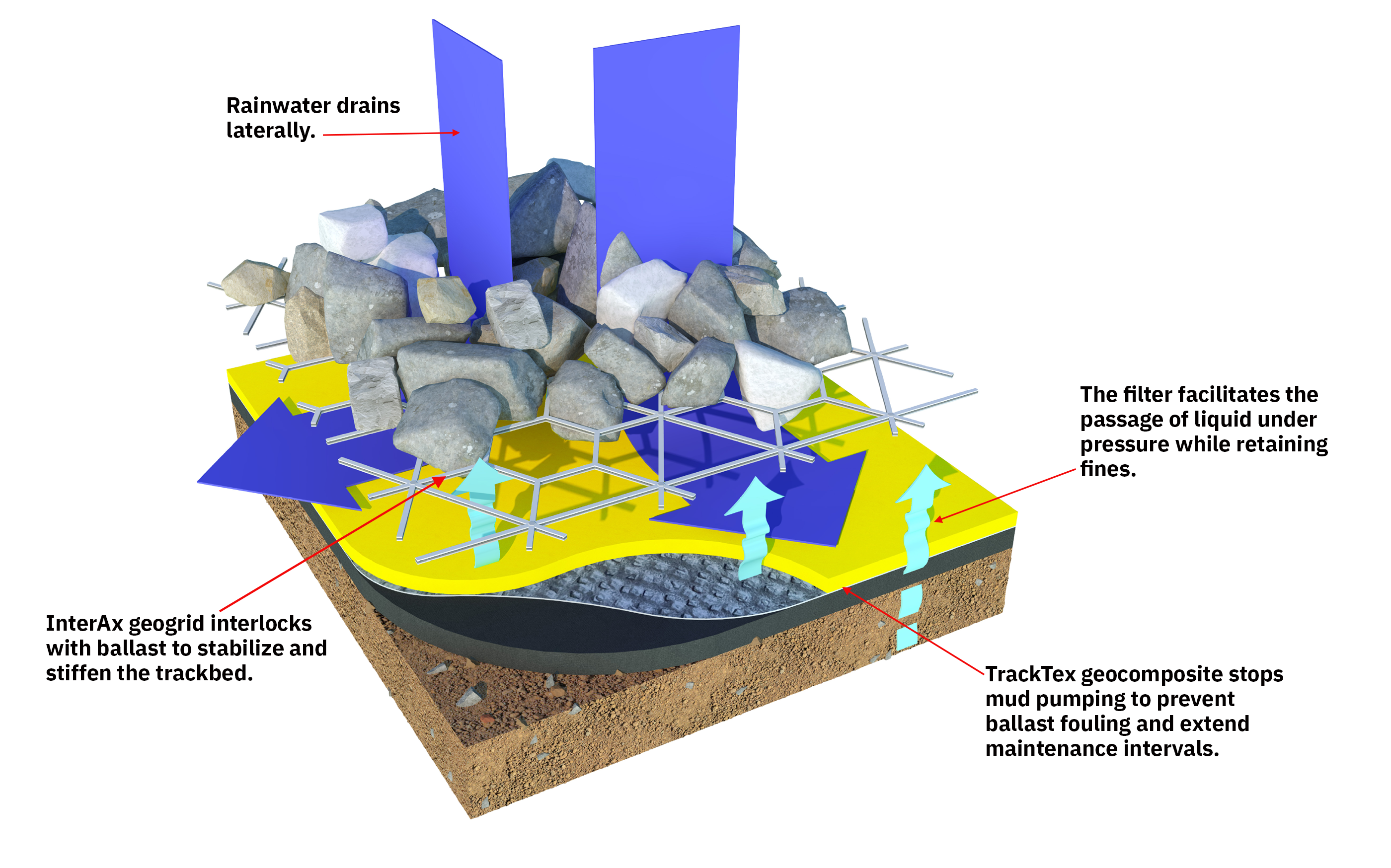

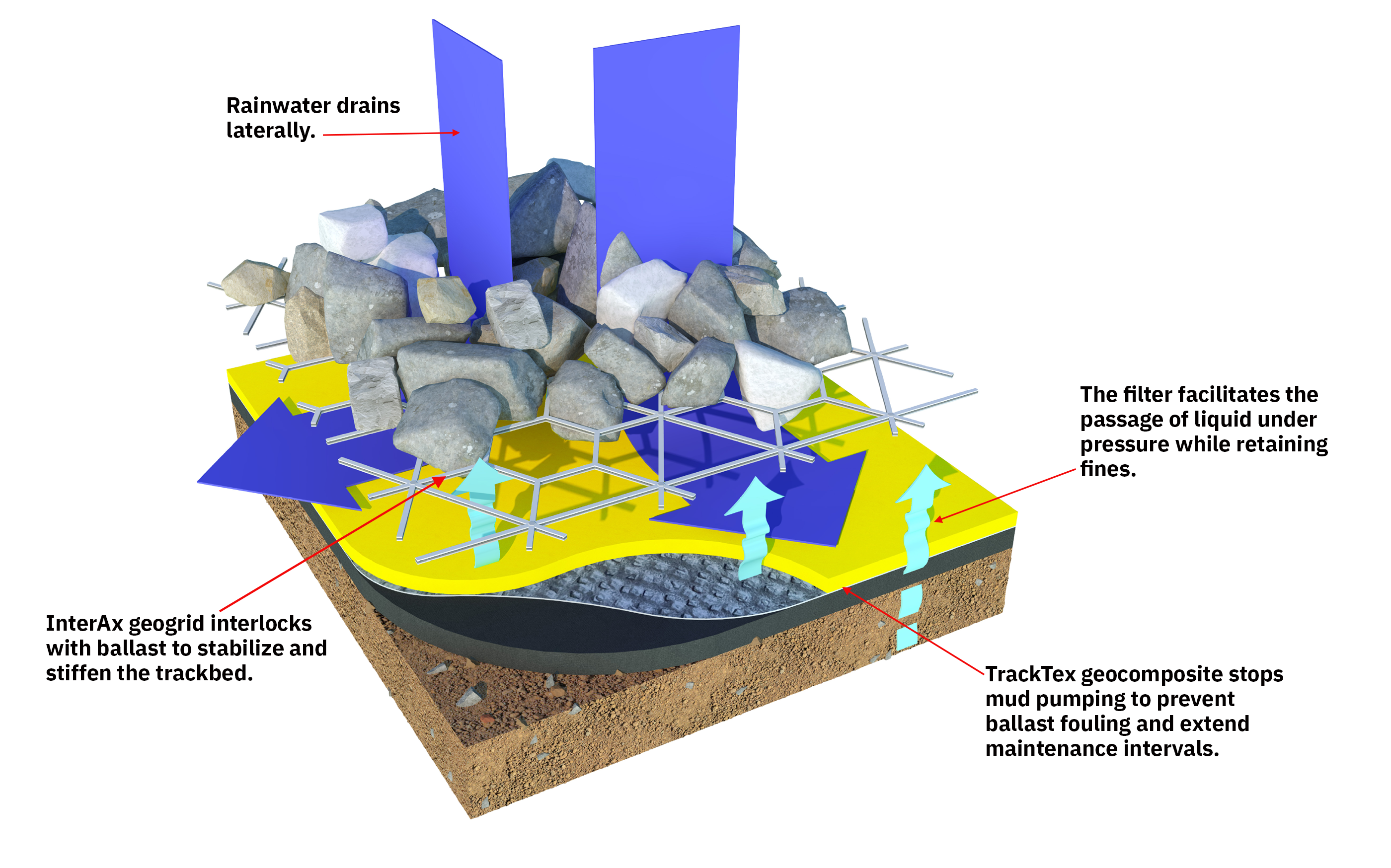

- Geogrids such as Tensar InterAx geogrids, are open, grid-like structures placed in the ballast and/or sub-ballast layers to confine the materials and create a stiff, mechanical stabilized layer. This layer better distributes loads, enabling reliable track performance without the need to excavate and replace subgrade.

- Geocomposites such as TrackTex combine layers like geotextiles and drainage cores to deliver filtration, separation, and moisture control. A key function is preventing fine particle migration, where tiny particles like silt or clay move upward into the ballast, fouling it and reducing its structural effectiveness.

By stabilizing weak soils and stopping the upward movement of fines, geosynthetics help keep ballast clean, stable, and long-lasting. The results include faster construction, fewer disruptions, lower maintenance needs, and a durable alternative to costly undercutting.

What Operations, Safety, and Asset Leaders Should Know

Stabilizing the subgrade in place using a solution that combines geogrid and geocomposites offers significant operational and strategic benefits:

- Reduced construction time: Faster installation minimizes construction windows and accelerates project timelines.

- Enhanced safety: Fewer trucks and reduced equipment movement result in a safer work environment for crews and lower risk to the public.

- Cost savings: Significant reduction in material handling and imported aggregate lowers overall project expenses.

- Extended maintenance intervals: Geosynthetics help preserve ballast quality, reducing fouling and the frequency of rework or tamping.

- Environmental sustainability: Reducing the number of truckloads and shortening work durations results in measurable reductions in CO₂ emissions, supporting agency sustainability goals.

- Supported by AREMA: Both geogrids and geocomposites have their own specification sections in Chapter 1, Sub-section 10 of the Manual for Railway Engineering

When This Approach Makes Sense

Excavation-free stabilization using geogrid and geocomposite materials are well-suited to the realities of modern rail infrastructure projects, especially in places where time, access, and soil conditions complicate traditional construction methods. This approach can offer substantial advantages when:

- Site access is limited, like in dense urban corridors or constrained rights-of-way, where large equipment and material hauling are disruptive or impractical.

- Construction windows are tight, requiring fast installation to avoid long service interruptions or scheduling conflicts.

- Subgrade soils are often poor or variable, especially in areas with pumping-prone soils, standing water, or a history of poor compaction performance.

- Projects are in early planning stages, allowing design teams to proactively identify likely issues and incorporate stabilization into the cross-section rather than reactively undercutting during construction.

- Agencies are seeking long-term performance, since stabilizing the trackbed with geogrid and geocomposite solutions can extend maintenance intervals and support broader resilience and sustainability goals.

The Chicago Transit Authority (CTA) faced significant challenges between the Dearborn Subway and Illinois Medical District Station due to subgrades with an Initial Bearing Value (IBV)—a measure of soil strength and ability to support heavy loads—below 4%, combined with poor drainage and restricted site access. Conventional methods would have required extensive excavation, importing large volumes of aggregate, and causing considerable delays. The use of geosynthetics drastically reduced site traffic, limited heavy equipment operation in congested areas, and enabled efficient construction without the typical urban disruption.

.jpg?lang=en-US&height=263&width=350) The CTA project team implemented an innovative approach using Tensar InterAx geogrid combined with TrackTex anti-pumping geocomposite. The complete solution involved placing 8 inches of sub-ballast and 12 inches of ballast on top of the geogrid and geocomposite materials, eliminating the need for excavation.

The CTA project team implemented an innovative approach using Tensar InterAx geogrid combined with TrackTex anti-pumping geocomposite. The complete solution involved placing 8 inches of sub-ballast and 12 inches of ballast on top of the geogrid and geocomposite materials, eliminating the need for excavation.This method resulted in significant savings: approximately $500,000 in project costs, nearly 1,200 truckloads of material avoided, and a reduction of over 50 tonnes of CO₂ emissions. The track installation was completed on schedule, minimizing disruption to surrounding roads and infrastructure.

Rethinking the Trackbed

CTA's success with excavation-free stabilization on the Congress Line is not an isolated case—it's a compelling model for more efficient, effective, and sustainable trackbed rehabilitation. As rail agencies nationwide tackle aging infrastructure, they have a clear choice: continue traditional excavation methods or adopt innovative, scalable, and low-disruption alternatives.

Agencies exploring this approach can benefit from early planning, supported by case studies, design tools, and field-proven insights available through Tensar. Early engagement helps identify opportunities to deliver measurable gains in cost, time, and environmental impact. When used strategically, excavation-free stabilization isn’t a workaround, it's a forward-looking upgrade to how you can build and maintain trackbeds.