SR-4 Pavement Rehabilitation

Ohio DOT Chooses InterAx® geogrids to Solve Old Problem

Owner: Ohio DOT

Civil Engineer: Chagrin Valley Engineers

Contractor: Barrett Paving

Distributor: Meredith Brothers, Inc.

The SR 4 project area sits atop a former municipal landfill that was active in the 1950s. Settlement had occurred through the years due to degradation of buried materials. The previous pavement continued to “washboard” as a result of movement in the lesser compacted fill areas. Soil borings and DCP tests (1958–2021) revealed varying depths of refuse (0–15 feet) and layered fill with dense gravel, sand, silt, and debris. Pavement cores showed increased asphalt thickness—up to 36 inches—in sections with prior settling, deviating from original 19-inch composite pavement design. Multiple geotechnical studies were undertaken to investigate long-term structural stability. Existing fill thickness ranged from 3.3 to 23 feet, while refuse layers were 3 to 18.5 feet thick and contained construction debris. Underlying soils included dense gravel, sand, and glacial till. Due to constant deterioration of the rideability and safety of the road it was determined that a geosynthetic solution would be constructed.

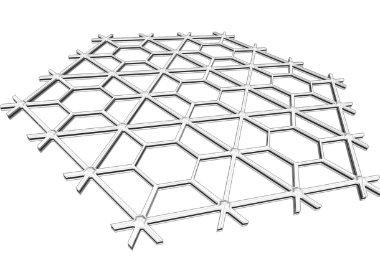

The contract called for over 20,000 cy of excavation/removal. The geosynthetic design used InterAx NX850 FilterGrid at the base layer with two layers of NX850 along with existing materials to create the mechanically stabilized layer. The Tensar solution will reduce constant maintenance issues on this section of SR4. The road that was once renowned for its washboard ride and had been a thorn in the side of ODOT can now be a smooth ride for many years to come.