Navigating the Cement and Lime Shortage: Proven Alternative for Soil Stabilization

by Joe Heintz, P.E., on June 08, 2022

Industry associations are reporting that supply chain issues and increased demand are creating shortages with cementitious materials like cement, lime and fly ash that are typically used to stabilize soft subgrades. Many suppliers report they are restricted to small allocations, with most cement going into concrete production. Those in construction who depend on cement or lime stabilization for their projects are being forced to find an alternative or face costly demand delays.

Industry associations are reporting that supply chain issues and increased demand are creating shortages with cementitious materials like cement, lime and fly ash that are typically used to stabilize soft subgrades. Many suppliers report they are restricted to small allocations, with most cement going into concrete production. Those in construction who depend on cement or lime stabilization for their projects are being forced to find an alternative or face costly demand delays.

Tensar Geogrid: A Reliable Soil Stabilization Solution

Tensar geogrid is readily available, can speed construction schedules and significantly cut construction costs. By partnering with Tensar, you get:

-

An expert site visit with our experienced staff, to evaluate conditions, confirm design parameters and advise on installation

-

Project specific design, to meet or exceed the performance of the chemically stabilized section

-

Assistance putting together a comprehensive design submittal, including estimated cost, time, and other benefits of using geogrid. We can help with fast-tracking approval with the engineer or owner.

-

Product availability throughout the US and Canada through our comprehensive network of distributors, with delivery directly to your project.

-

Proven long term performance to ensure client satisfaction, minimize premature failure or warranty work for contractors

How do geogrids work? Tensar geogrids enhance performance of poor soils by interlocking unbound aggregate materials. As the granular material strikes through the geogrid openings they become laterally restrained and obtain a higher degree of confinement. This stiffer, stabilized layer resists rutting and improves bearing capacity and increases traffic capacity.

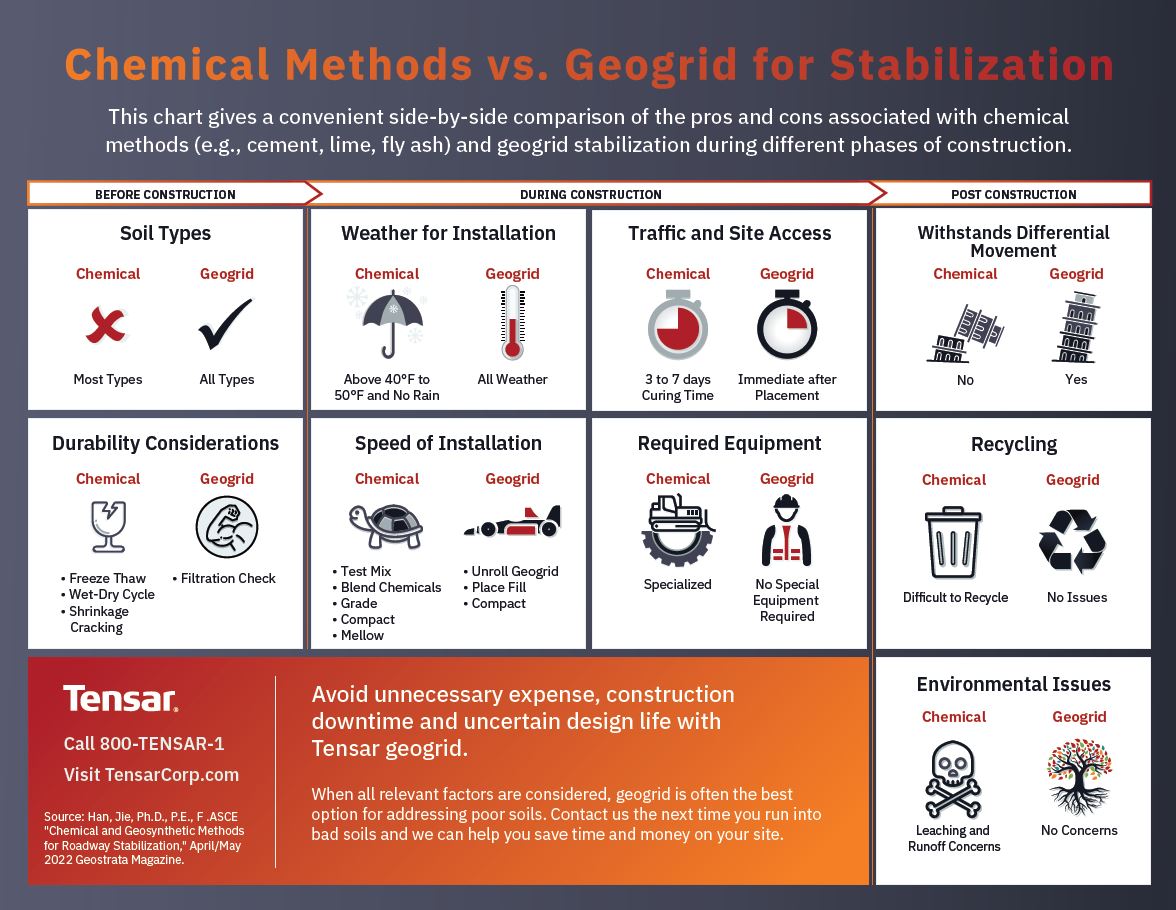

How do they save time? Chemical stabilization requires extra steps like soil testing for compatibility, specialized equipment, favorable weather conditions, and lengthy curing times. But these hurdles are avoided with Tensar geogrid. This chart gives a convenient side-by-side comparison of the pros and cons associated with chemical and geogrid stabilization through various stages of construction. Even when there is no raw material shortage, stabilization with Tensar geogrid is often the best option for addressing poor soils.

Click the image to download our handy comparison dashboard.

Proven Savings

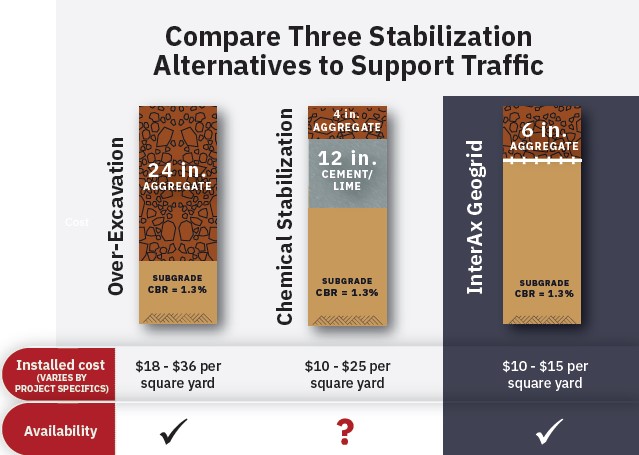

Tensar’s innovative geogrid technology provides effective confinement of granular fill, resulting in a stiff mechanically stabilized layer (MSL) capable of controlling differential settlement and increasing bearing capacity. This efficiency results in less required aggregate to achieve the same performance. And less aggregate means less cost. Take a look at the chart to compare over-excavation, chemical and geogrid soil stabilization methods.

Proven Technology

Tensar geogrids are backed by decades of rigorous laboratory evaluations, in-situ field testing and validated by 3rd parties to ensure you get a proven, data-driven solution. This data allows us to quickly generate an alternate geogrid design when chemical methods are not available. We’re here to support you with a proven solution that delivers greater total value.

Avoid further costly delays and contact us now. We will give you a free project review and fast-track an alternate geogrid design.