Creating Solid Ground from Soft Soil on Norfolk Southern’s Calumet Project

by Don Herbert, on August 15, 2025

When the ground won’t support itself, your operation—cranes, trucks, tight timelines—won’t wait. That was the challenge Tensar faced when Norfolk Southern planned to expand its intermodal operations in Calumet, Illinois. The subgrade there was extremely weak, measuring only 1.5% CBR, far below what’s needed to support heavy loads like gantry cranes and truck traffic.

When the ground won’t support itself, your operation—cranes, trucks, tight timelines—won’t wait. That was the challenge Tensar faced when Norfolk Southern planned to expand its intermodal operations in Calumet, Illinois. The subgrade there was extremely weak, measuring only 1.5% CBR, far below what’s needed to support heavy loads like gantry cranes and truck traffic.

Tensar’s Solution:

Using Tensar+ design software, engineers developed a tailored solution:

Using Tensar+ design software, engineers developed a tailored solution:

-

Use just one layer of Tensar's NX750 InterAx® geogrid placed beneath both flexible (asphalt) and rigid (concrete) pavement sections.

-

Design seven different pavement sections to match the diverse load demands of cranes, trucks, and parking areas.

-

This approach significantly reduced or eliminated the need for undercutting, cutting project cost and timeline.

The Outcome:

-

A durable, cost-efficient foundation that supported heavy-duty operations—cranes, trucks, dolly pads—without extensive excavation.

-

Accelerated construction and saved money compared to traditional methods.

-

Operations stayed on track, thanks to the stable subgrade and smart geogrid deployment.

Why InterAx® geogrid?

Why InterAx® geogrid?

-

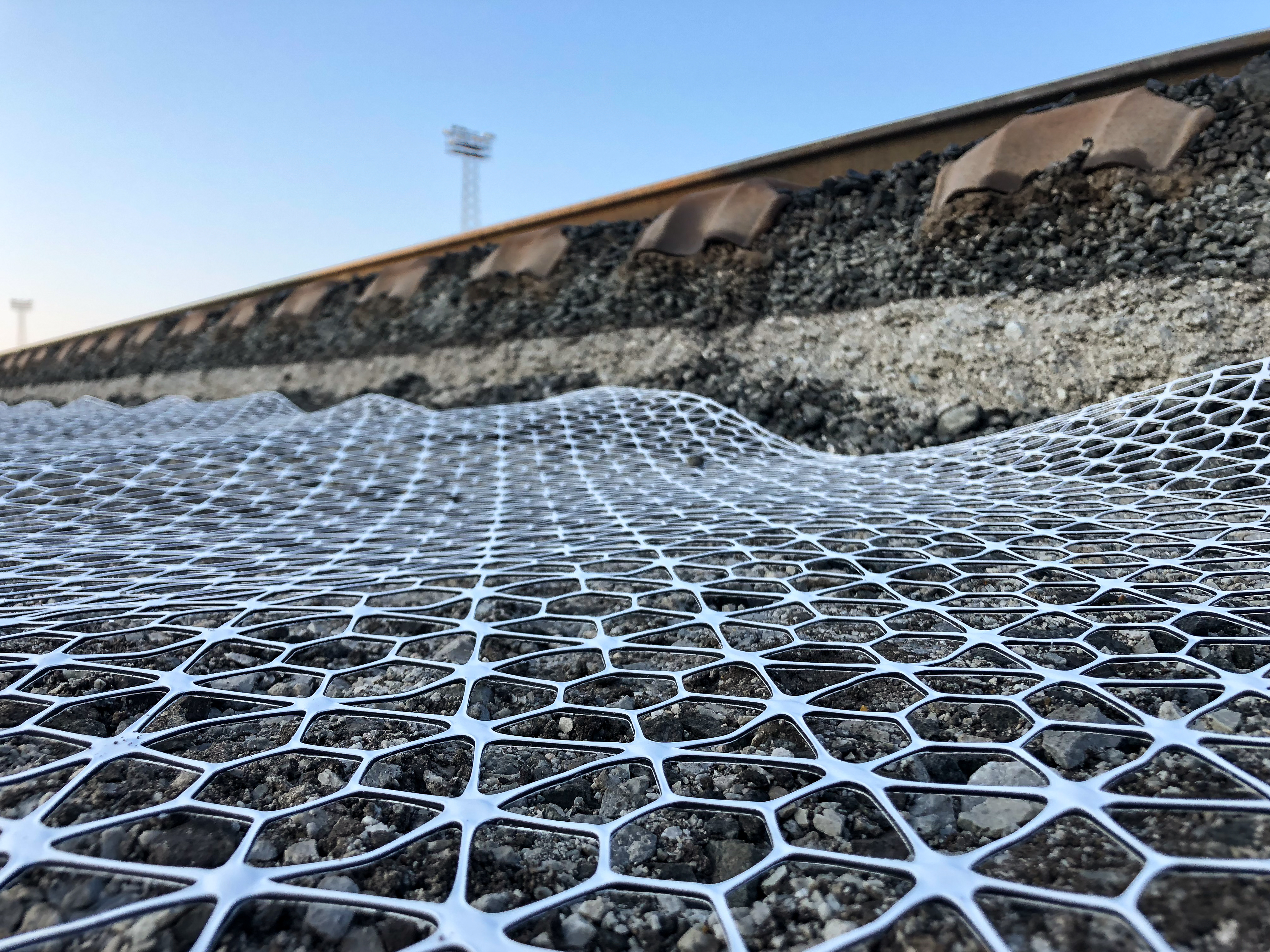

Geogrids, invented by Tensar nearly 50 years ago, are geosynthetic materials that reinforce and stabilize soils by interlocking with aggregate materials.

-

Tensar's InterAx® geogrids (like NX750) are built with unique openings and material strength designed to lock in aggregate and hold up even under heavy traffic and tough site conditions.

-

With Tensar+, engineers can design solutions that leverage thinner pavement layers and fewer excavation needs, without compromising strength.

Lessons from the Calumet Project

-

Test the soil—and trust the numbers. A 1.5% CBR is exceptionally weak. Geogrids offer a smart path when traditional removal isn’t feasible.

-

Design with precision. One type of geogrid, intelligently placed under different pavement types and load zones, can serve multiple functions.

-

Reduce excavation, not quality. Geogrids help save on haul-off and fill, reducing both cost and environmental impact.

-

Work with smart tools. Tensar+ helps engineers optimize soil geotechnical design for cost, time, and performance.

Heavy infrastructure doesn’t need heavy excavation. By combining geosynthetic engineering with clever design tools, Tensar delivered a cost-effective, durable foundation solution for Norfolk Southern—keeping operations where they belong: running.

- Watch an overview of this project on Beneath the Build.

- Learn more about Tensar solutions for rail or get in touch with your Tensar rep to see how geogrid can benefit your next project. Contact us now!