DOE Choctaw Well Pads

April 2020 - Jan 2021

Despite fat clays, cost-effective oil pads constructed on schedule using Tensar solution.

- Owner/Developer: Boardwalk Pipeline Partner

- Contractor: 2H&B, LLC

This DOE Petroleum Reserve consists of underground crude oil storage facilities on about 400 acres and stores more than 50 million barrels. When it was decided to expand the storage capabilities in 2019, the engineers found the site conditions extremely challenging. Testing indicated fat clays were the predominate soil type meaning the potential for shrink-swell was high. It was imperative that the drilling rigs have very minimal differential movement while mobilized and operating on the well pads.

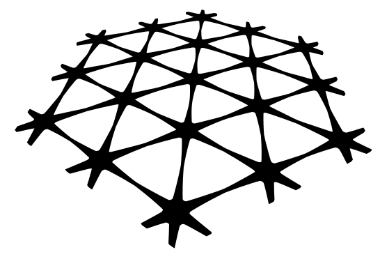

The overall objective was to create a strong working surface and mitigate the moisture felt by the fat clay. Tensar geogrid-stabilized surfaces were designed that included a lean clay layer to reduce the moisture that filtrated down through the pads. At least six inches of existing natural ground was removed and leveled and a layer of Tensar geogrid was placed directly on the fat clay. Next, a minimum 12“ thick uncompacted sand layer was placed to drain moisture horizontally instead of vertically. On top of the sand layer, loose lifts with a minimum 8” thick lean clay was placed. This cap of lean clay provided a moisture barrier to isolate the underlying “fat clays” from the changes due to moisture variations and contributed to the overall strength of the section.