Using Tensar TriAx Geogrid Solutions for Landfill Projects

by Tensar International , on July 12, 2019

Many times there is great risk associated with constructing over a closed landfill. The unknown composition and degradation of the underlying fill can often be a challenge to assess. Differential and total settlement can cause unwanted problems for structures, pavements, or roads that are built over closed landfills.

THE TENSAR SOLUTION

Although these landfill properties are cheap and often located in favorable locations, many consider these sites un-constructable. However, with Tensar's TriAx Geogrid solutions, these landfill sites become viable, cost-effective options often bringing substantial savings to the owners and land developers.

Although these landfill properties are cheap and often located in favorable locations, many consider these sites un-constructable. However, with Tensar's TriAx Geogrid solutions, these landfill sites become viable, cost-effective options often bringing substantial savings to the owners and land developers.

THE TRIAX ADVANTAGE

TriAx Geogrid is a geosynthetic material used to stabilize soil. Geogrids have openings, called apertures, which allow aggregate to strike through and provide confinement and interlock. Since TriAx Geogrid greatly minimizes the movement of aggregate, a stiff platform over weak, compressible soils is created in the aggregate layer. The stiffened aggregate results in an enhanced load distribution beneath the large static and dynamic loads imposed by the heavy loads. This increases the factor of safety against a bearing capacity failure in the subgrade.

TriAx Geogrid is a geosynthetic material used to stabilize soil. Geogrids have openings, called apertures, which allow aggregate to strike through and provide confinement and interlock. Since TriAx Geogrid greatly minimizes the movement of aggregate, a stiff platform over weak, compressible soils is created in the aggregate layer. The stiffened aggregate results in an enhanced load distribution beneath the large static and dynamic loads imposed by the heavy loads. This increases the factor of safety against a bearing capacity failure in the subgrade.

What does TriAx technology mean for your landfill project?

Lower Costs: Using less aggregate with an increased speed of construction yields significant cost savings. These cost savings increase with greater traffic loads and weaker subsoil conditions. TriAx has saved developers as much as $1 million on individual projects.

Increased Speed of Construction: The installation process for geogrids is extremely straightforward. Using less aggregate leads to quicker installation when compared to other landfill solutions that use conventional soil stabilization techniques.

Avoid Over-Excavation: Traditional stabilization often involves over-excavation and disposal of the uppermost subgrade soils.

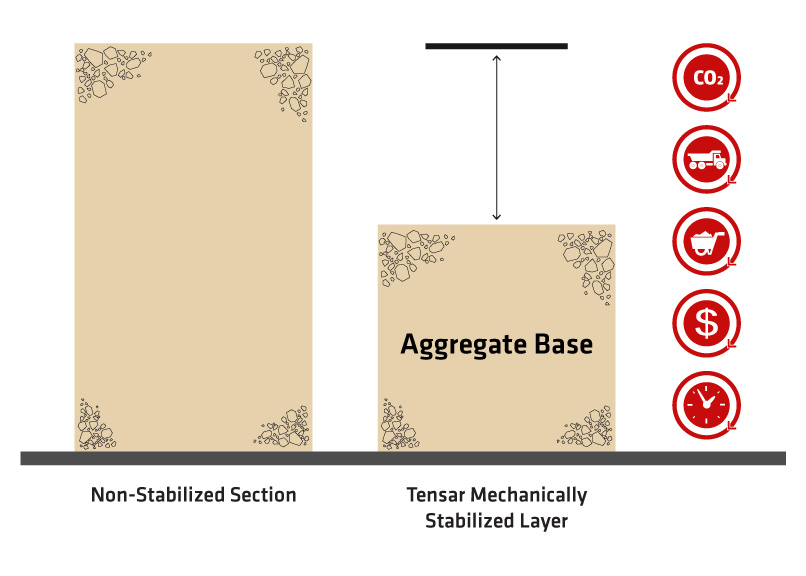

Less Aggregate: The latest Giroud-Han design methodology has demonstrated that the required aggregate thickness can be reduced by up to 60% for roads reinforced with Tensar TriAx Geogrids with no loss in performance.

Less Aggregate: The latest Giroud-Han design methodology has demonstrated that the required aggregate thickness can be reduced by up to 60% for roads reinforced with Tensar TriAx Geogrids with no loss in performance.

Eliminate Uncertainties Associated with Chemical Stabilization: Apart from the obvious environmental concerns, chemical treatment of the subgrade requires that optimum temperatures and dry weather conditions be met. This can lead to delays in the construction process.

Reduce the Potential for Differential Settlement: Multiple layers of Tensar TriAx Geogrids in a granular layer create a flexurally stiff platform over variable soil conditions.

MAXIMIZE TIME AND COST SAVINGS WITH TENSAR DESIGN SOFTWARE

The Giroud-Han design method was published in the August 2004 edition of the ASCE Geotechnical Journal. The paper reveals the most significant advancement in the design of geosynthetic-reinforced roads within the last 10 years. Tensar developed Tensar+ in order to offer Engineered Solutions compliant with the latest design methodology.

Available free of charge, Tensar+ allows the removal of uncertainties associated with the cost and reliability of access road construction. This is particularly important when dealing with heavy loads and weak soils, as it also allows the developer to minimize the cost of these components.

Tensar, engineered to help.

At Tensar, finding solutions that lower construction costs and bring added value is our top priority. That’s why we put our experts to work, showing contractors and engineers around the world how to build smarter infrastructure using geogrid technology. With decades of research and real-world experience under our belt, our geogrid solutions bring significant cost and time savings across a wide range of civil applications like soil stabilization, pavement optimization, and landfill projects.