Phased Asphalt Road Construction: Method Benefits & How to Optimize Layers

by Joe Heintz, P.E., on May 21, 2019

Phased construction has become a widely used approach in residential developments, where quick access and scheduling flexibility are essential. In this method, contractors build the initial roadway by installing the aggregate base and a binder layer of asphalt. The final surface layer is added later—typically after utilities have been installed and other site work is complete—resulting in a clean, finished appearance.

This staged process is especially practical when trenches are needed for underground pipes or cables. However, while the phased construction method offers short-term efficiency, it can lead to long-term pavement performance issues if not properly planned. In this article, we’ll explore why that happens—and how to build smarter from the start.

Performance Implications

Cracking at the surface is a common issue for phased asphalt road construction, particularly in new housing subdivisions. In many cases, pavement distress in the form of cracks begin to appear within just a year or two of completion.

Once cracks form, pavement deterioration tends to accelerate. Patterns like the “alligator” cracking shown in the third photo below usually indicate deeper structural problems. At that point, simple resurfacing won’t fix the issue. Instead, the road owner may be forced to replace the foundational asphalt road construction layers, which is far more costly and disruptive.

So what’s going wrong beneath the surface—and how can we avoid it?

Cause of Premature Pavement Failure

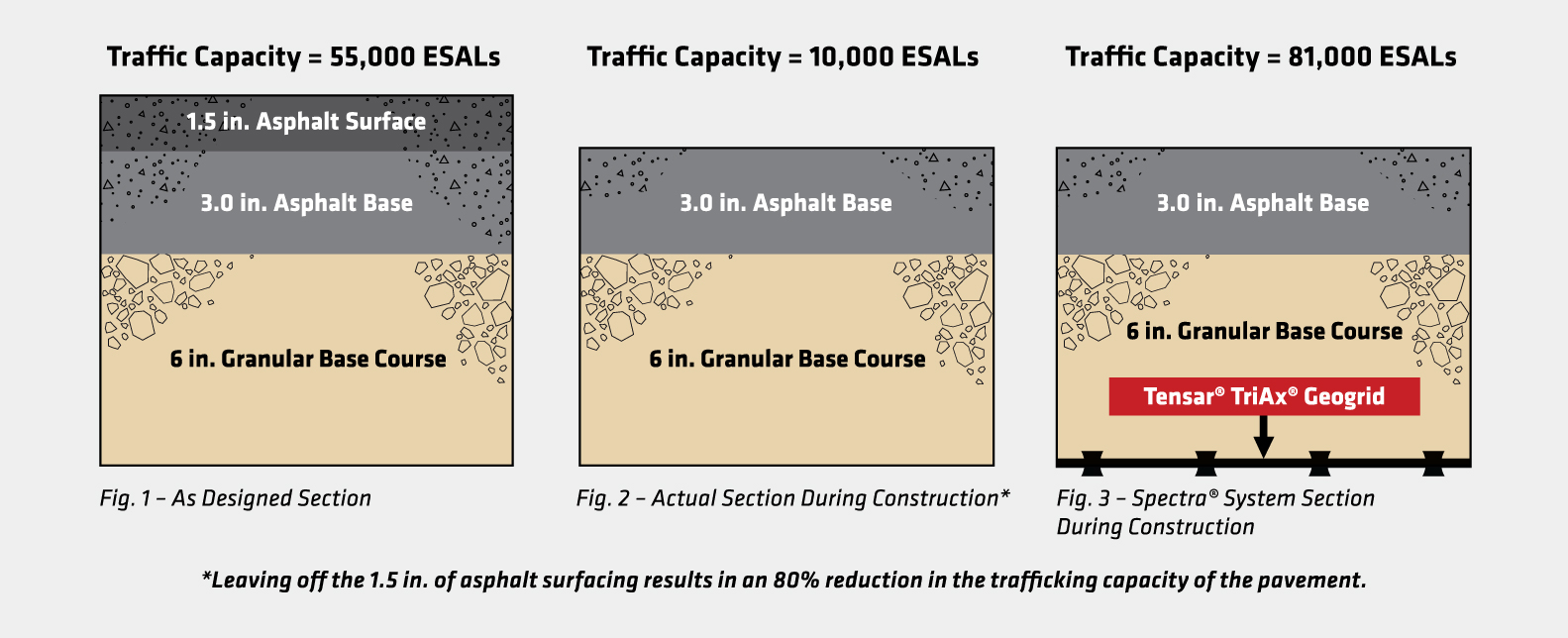

To understand the problem, consider the pavement design comparisons shown below. Using the American Association of State Highway and Transportation Officials' (AASHTO) design method for flexible pavements, the diagrams demonstrate how load capacity—measured in Equivalent Single Axle Loads (ESALs)—drops when the final surface layer is delayed.

Leaving off just 1.5 inches of surface asphalt during phased asphalt road construction can reduce the pavement’s ability to handle traffic by up to 80%. That’s especially concerning on subdivision roads, where the heaviest traffic often occurs during the construction of homes and infrastructure.

It is not surprising then, that when the asphalt surface layer is installed at the end of phased construction, the rest of the road is approaching the end of its design life. The placement of the surface layer results in some additional trafficking capacity, but after a year or two, the road will start to show surface distress – indicative of structural integrity problems associated with the lower layers.

By the time the top asphalt layer is finally installed, the road’s structural base may already be worn down. Although the surface layer adds some strength, it usually isn’t enough to reverse the damage that’s already been done. As a result, surface pavement distress returns within a a year or two—signaling the need for costly repairs that could have been avoided.

A Smarter Way to Build in Phases

Fortunately, there’s a proven way to reinforce asphalt roads during phased construction—without changing your schedule. For over two decades, extensive research, monitoring, and project data have shown that the inclusion of geogrids within the aggregate base can significantly improve pavement performance. In this specific application, Tensar's TriAx® Geogrid makes up for the temporary absence of the final surface layer by stabilizing the base and distributing loads more effectively. Roads built this way not only maintain their design strength during construction, but often outperform the original specifications over time.

In short, incorporating geogrid in early asphalt pavement layers helps preserve the structure, reduce maintenance, and extend pavement life—all without disrupting the phased construction process.

Design Tools

To help engineers and contractors make informed design decisions, Tensar offers Tensar+™, our user-friendly pavement design software. This tool allows you to model different pavement structures, analyze performance under various conditions, and optimize material use based on your project needs.

Whether you’re working with full-depth asphalt, flexible pavements, or reinforced aggregate bases, Tensar+™ makes it easier to evaluate the benefits of using geogrid in your design.

How Can We Help?

At Tensar, we’re dedicated to helping clients reduce costs and improve long-term value. That’s why we share our decades of expertise in asphalt road construction, showing contractors and engineers how to build stronger, more reliable roads using geogrid technology.

If your next project involves phased construction, we’re here to help you design it smarter from the start. Watch how TriAx Geogrids work or click below to find out more about how we can help you build better pavements—on schedule and on budget.