Beneath the Build: Choosing the Best Geogrid

by Katie Phillips, on May 09, 2025

Not All Geogrids Are Created Equal

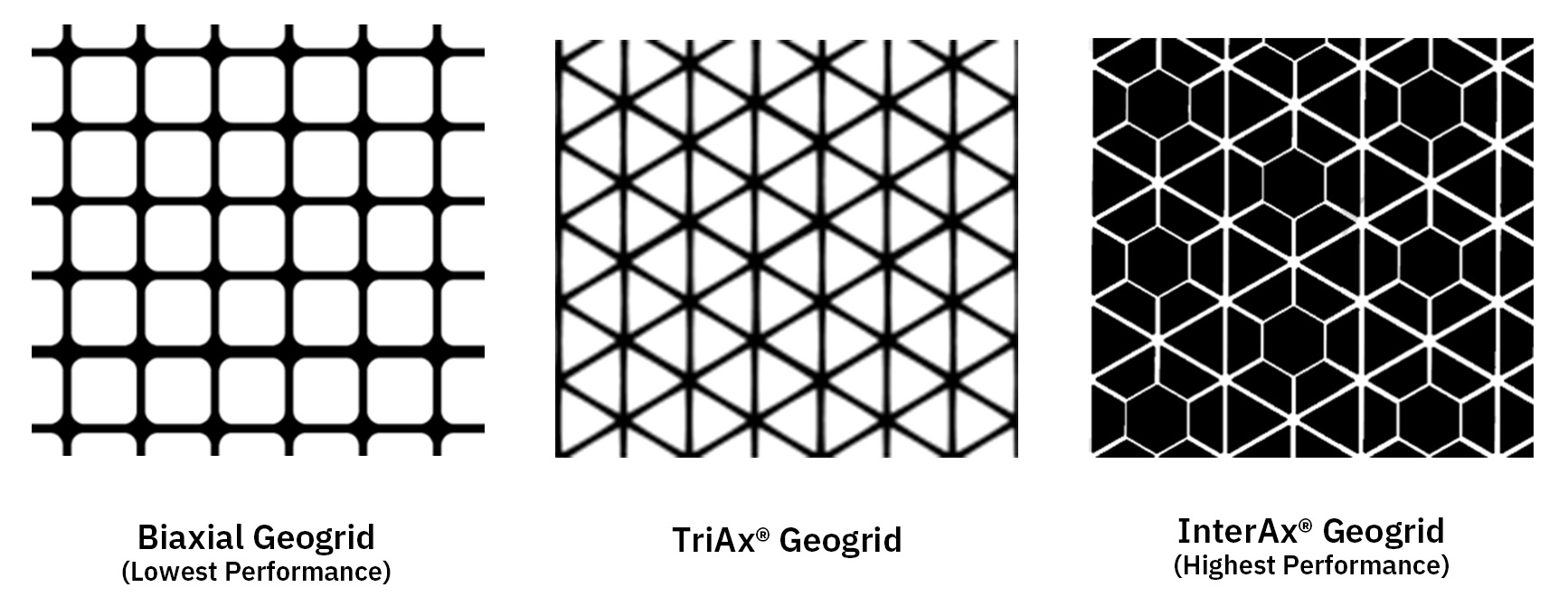

Geogrids come in various forms—biaxial (BX), triaxial (TX), and multi-axial InterAx (NX)—each with different geometries, materials, and performance profiles. While they might look similar, their functionality can differ significantly based on both shape and material properties.

For example, two geogrids with the same aperture shape may behave very differently in the field if they’re manufactured with different polymers. This makes performance validation data, not just index properties critical to the decision-making process. We will discuss this more next week.

Understanding the application and performance goals for the project are essential to choosing the correct geogrid. For example, high-performance applications like crane pads and permanent roads , InterAx often provides superior strength and requires less aggregate, which can save both time and material costs. On the other hand, the H-Series geogrids offer an economical solution for low-risk or temporary applications where performance thresholds are more forgiving.

Understanding the application and performance goals for the project are essential to choosing the correct geogrid. For example, high-performance applications like crane pads and permanent roads , InterAx often provides superior strength and requires less aggregate, which can save both time and material costs. On the other hand, the H-Series geogrids offer an economical solution for low-risk or temporary applications where performance thresholds are more forgiving.

Key Takeaways

Choosing the right geogrid can be the difference between a blown budget and a successful project. When choosing the best geogrid, remember:

-

Know your application – Match the geogrid to the risk level and project demands.

-

Think beyond material cost – Account for total installed cost, including aggregate needs.

For questions or site evaluations, contact your local Tensar expert

Did you miss this episode or want to re-watch? Check it out here.