Pavement Design: Why Physical Geosynthetic Properties Don’t Matter

by Bryan Gee, P.E., on September 14, 2023

Over the last few decades, numerous research projects have been conducted which studied how the physical properties of geogrids relate to performance. To date, no correlation between physical properties and performance has been documented. In an effort to claim equivalence under construction specifications, many geosynthetic manufacturer and supplier sales representatives routinely misrepresent this fact by publishing product data sheets that compare selected physical properties between products. The situation is further confused because many public agencies do not have performance-based specifications, so they default to specifying products based on physical properties.

.jpg) The reliability of the pavement design becomes compromised when product selection is based on physical properties since those properties are not inputs to any validated flexible pavement design method. Proper pavement design looks at how all materials and loading conditions work together, including geosynthetics if they are used. Each geogrid product has different rib orientations, geometries, materials, rib structures, and many more features which determine how that product interacts with aggregate. Differences in aggregate quality, asphalt types and thicknesses, and other variables must also be considered.

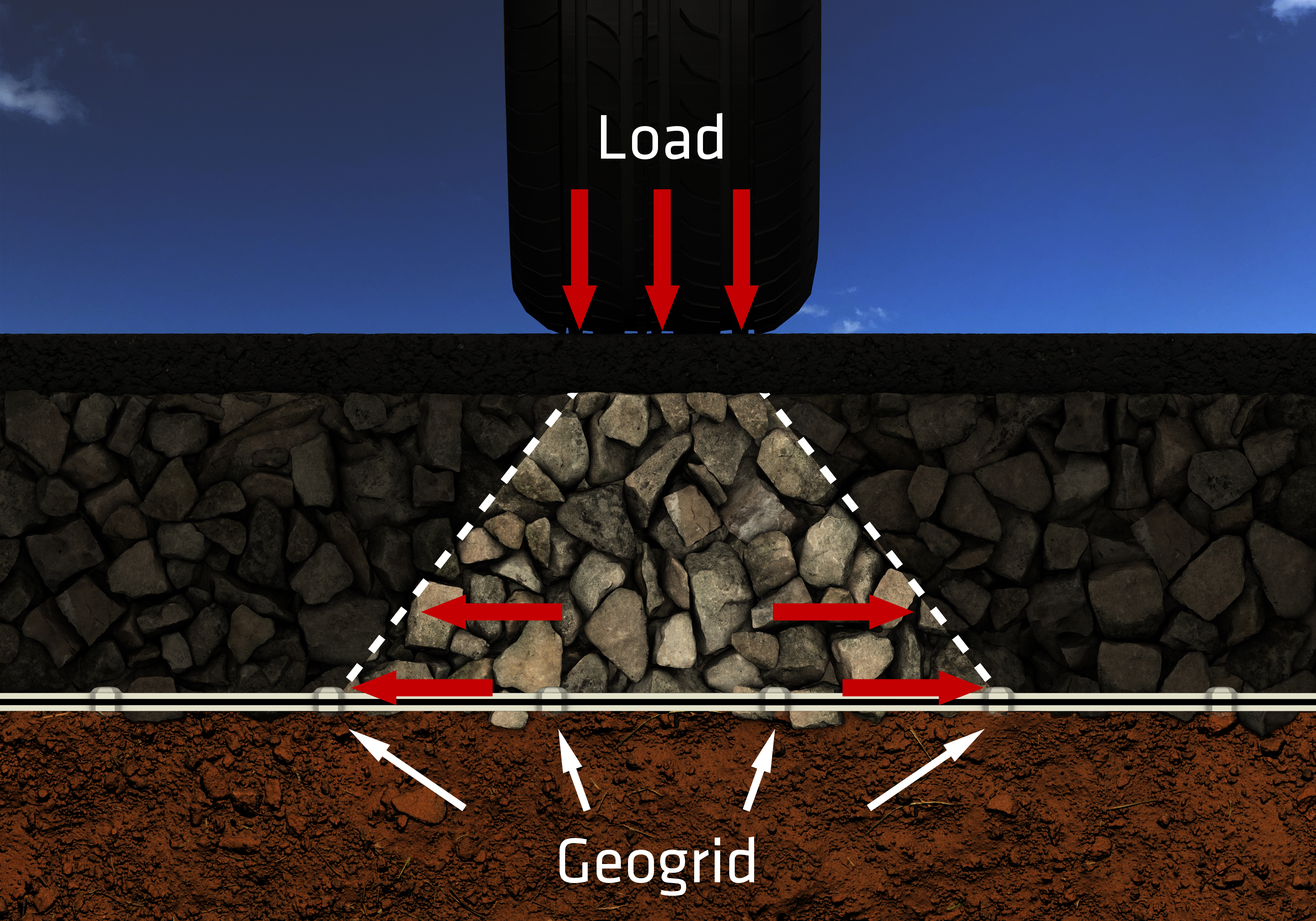

The reliability of the pavement design becomes compromised when product selection is based on physical properties since those properties are not inputs to any validated flexible pavement design method. Proper pavement design looks at how all materials and loading conditions work together, including geosynthetics if they are used. Each geogrid product has different rib orientations, geometries, materials, rib structures, and many more features which determine how that product interacts with aggregate. Differences in aggregate quality, asphalt types and thicknesses, and other variables must also be considered.

Geosynthetic performance must be empirically tested and evaluated in order to develop the proper parameters to be used in a design. AASHTO has a documented process for evaluating and designing geosynthetic-stabilized aggregate base courses in flexible pavement. This standard of practice is outlined in AASHTO R50-09 and recommends that pavement designers verify the design parameters used. The design parameters should be based on predictive models developed through significant testing on each product considered.

Applied Research Associates (ARA) Quotes from both their own review and referencing FHWA, 2013:

“Products submitted as equivalent shall have documented equivalent or better performance in pavement stabilization in laboratory tests, full-scale tests, and completed project experience for the project conditions (base course material and thickness, failure criterion, subgrade strength, etc.) The alternate geogrid modified layer coefficient calibration and validation shall be evaluated by a third party. Assessment report, by the third party, shall accompany the submittal, and with the qualifications summary of the third party reviewer.”

If you would like to gain a better understanding of the different types of specifications and how each ensures performance, then check out this webinar, “Specification & Performance Validation Strategies.”