Comparing Giroud-Han and LAAMS for Geotextile Reinforced Unpaved Road Design

by Bryan Gee, P.E., on June 09, 2023

There are several design methods available for subgrade stabilization. The applicability, precision, and limitations of these methods vary significantly: the designer should make every effort to ensure the method used is appropriate for the specific design conditions of each project. Also, as is true for all types of engineering, the use of more precise and sophisticated design methods will result in more reliable results and lower risk of failures.

When geosynthetics were first used for subgrade stabilization, designs were based purely on experience and rules of thumb. More than 50 years later, one can still see instances where this is the case: for example, there might be a provision in a specification that states that if unexpected soft soils are encountered, the contractor should excavate the top two feet, place a geotextile, and add select fill or aggregate back to finished grade. While this may be sufficient to solve the problem, the engineer and the contractor will not know if the solution works until after it has been installed. Further, they will have no way of knowing if the problem could have been solved more efficiently, for example with less fill.

Later, experts in geosynthetics developed design methods for subgrade stabilization, focused on unpaved (gravel-surfaced) roads with channelized traffic. The most notable and widely accepted of these methods were developed by Giroud and Noiray (1981) and Giroud and Han (2004). The Giroud-Han design method has been widely used for unpaved road design over soft soils over the past decade or so. The method is valid for applications within the following limitations:

- 40 kips maximum axle load

- Surface rut depth at failure between 1.5” and 4.0”

- 10,000 maximum axle passes

- Subgrade CBR between 0.4% and 4%

- Channelized traffic only

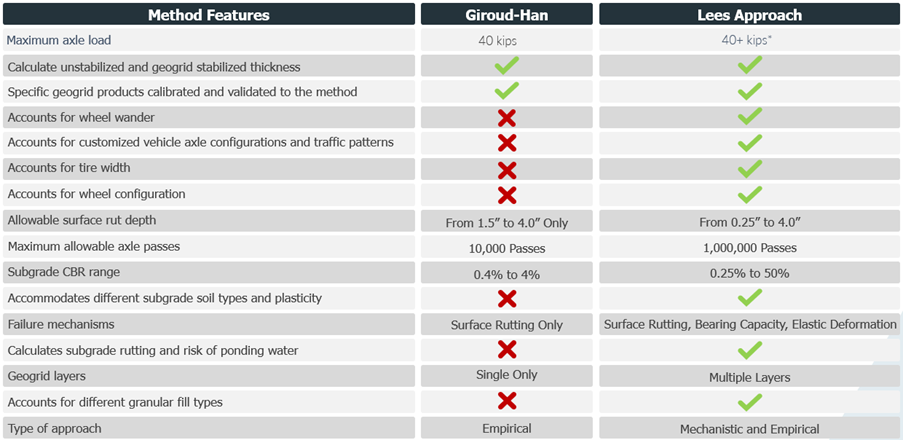

While Giroud-Han allowed many subgrade stabilization applications to be designed more precisely than earlier approaches, there are many instances where the requirements of the design fall outside these limitations. These include complex traffic patterns, multiple vehicle types, heavier vehicles, and different failure criteria. To address these needs, Tensar has introduced a new design approach for designing stabilization applications using geogrids, the Lees Approach to Applied Mechanical Stabilization, or LAAMS.

LAAMS goes beyond the capabilities of the Giroud-Han method in several important ways, as shown in the table below. This allows engineers to develop more precise and reliable designs for a much wider range of conditions, reducing failure risk while maximizing project value. Tensar+ software now uses LAAMS as the preferred method for subgrade stabilization designs. InterAx geogrids have been tested and calibrated to this method to ensure the most reliable, highest-value solutions can be designed quickly and easily.

Project Example: Access road design using LAAMS approach saves time and money

What do nearly 9,000 dump truck deliveries and 1,250 concrete trucks have in common? They all would wreak havoc on an access road with a lean to fat clay subgrade with a California Bearing Ratio between 1%-2%. The importance of reliable performance of the access road during construction cannot be overstated.

A temporary access road was required during the construction of an addition to the Meijer Distribution Center. The poor soil conditions of fat clays, which are sensitive to disturbance and moisture, were encountered throughout the site. The site was also located in a freeze/thaw area, which adds an additional mechanism for subgrade deterioration and failure. It was critical that the access road remain serviceable so that construction stayed on schedule. Additionally, the owner of the project is considering the eventual paving of the haul road, making protecting the subgrade even more critical.

The original unstabilized design required 29” of aggregate. Using data supplied by Meijer and its geotech, Tensar developed a solution using the LAAMS design approach in Tensar+ design software. This stabilized design using InterAx geogrid provided a cost-effective solution that controlled surface and subgrade rutting. Also, it gave the owner the option of paving the road in the future without conducting extensive earthwork repairs.

The original unstabilized design required 29” of aggregate. Using data supplied by Meijer and its geotech, Tensar developed a solution using the LAAMS design approach in Tensar+ design software. This stabilized design using InterAx geogrid provided a cost-effective solution that controlled surface and subgrade rutting. Also, it gave the owner the option of paving the road in the future without conducting extensive earthwork repairs.

The bottom line: these goals were achieved by reducing the required aggregate to 14 inches. This saved an estimated 8.5 days of construction time and approximately $25k in construction cost of the access road.

If you want to learn more about using the LAAMS design approach for future unpaved road projects then watch our on-demand webinar.